I might also compare what I saw using this knife to what some other said about it and say it if think otherwise but don't mean disrespect if I do: I'm simply giving my thought about what I expected from the review and what I then felt using it. Please restrain from going into offensive post against me or other as we are all entlited to our own opinion and can speak it out without being disrecpectful. Pictures quality aren't as high as some other poster as I'm using a cellphone to take them and weather has been rainy lately, which doesn't help at all.

Edit - Added pictures to show difference in sharpening the 10V vs Superblue

The First Look:

As most of you already know, this isn't the smallest folder in Spyderco line up. This one is big. How big you ask?

When I got the shipment from CS, I quickly opened the package and flicked open my new toy after a quick look at the knife itself. The first thing that hit me in the head was : "That thing is a beast!"

Then, after gazing in admiration at the K2 for an unknown time lapse, a second thought came at me. How and when was I gonna carry something that big and let's say... intimidating? I seriously started to felt scared about making a bad choice when I ordered the knife while at the same time being completely in love with the knife. It was like having the "devil/angel" thing speaking to me two different thing at the same time. An easy way to illustrate how I felt:

First exploration:

I couldn't keep gazing at it this way forever, excited but undecided about how I really felt. I had to try to find a way to help myself figure it out. Out of the few knives I own, most are of what people here on the forum would call "most blade for the value" type. They all are user that are being put to use daily and choose the cheapest model offering blade shape/steel I needed, putting aside artificial needs and wants such as better handle materials/ergo. Guilt about spending that much money on a knife simply because I wanted it, not because I needed it, was a first for me. In fact, it took myself a few week to justify to myself spending 100$ for that SB stretch that I use daily at work and even then, knowing I could have used one of the Byrd by sharpening more frequently sometime made me felt guilty at first. So now this K2 impulsive buying was hard to justify and **** was the timing bad. I learnt the same day I received the package that my job site would close 3 months earlier then expected and that I was about to stay home for an unknown period.

The best way to be able to stop the trance was by closing it and so did I. It made me realize that what some other already said about sticky lock wasn't the thing of only 1 in a hundred knives as mine did the same. I flicked it a few times compulsivly to see if it would go away quickly but it didn't so I stopped for now. I guess time will smooth things out. Flicking it this way, on the other hand, made me realize three thing:

- Despite his size and weight, the K2 open up quickly. Really quickly in fact. The action is the smootest of all the Spydies I owned, may it be brand new and even after burning in time.

- The lock-up on the knife is awesome. Every time you flick the knife, the lock fall in it's place with a notorious and authoritative "snap". The particular noise it make when engaging is the same if not better then saying out loud "Watch out, big boy is out!"

- Lock-up is somewhat late for some if not most taste. I personally don't mind this as the solid feel it has doesn't give any hint it could fail anytime soon.

Blade centering is perfect and it fall right in the middle when closing it. Couldn't ask for more.

The grind is also perfectly spot on middle. Sorry no pictures on that one.

The stonewash finish on the titanium handle is appealing to me. I can't tell for every one since it's a question of which kind of look you like, but it's better then plain satin finish in my mind as a knife I own will be used without babying it and scratches will be less catchy to the eye with this kind of finish.

I then decided to compare it size by size with the others folder I have (ain't many as I said earlier) so I'll leave a few pictures so you can see for yourself.

Next to my SB Stretch

Next to my SB Ladybug (the only extra "just in case I lose it" knife I own, you can notice from how clean compared to the other 2 it is)

The 4 together

Ergo:

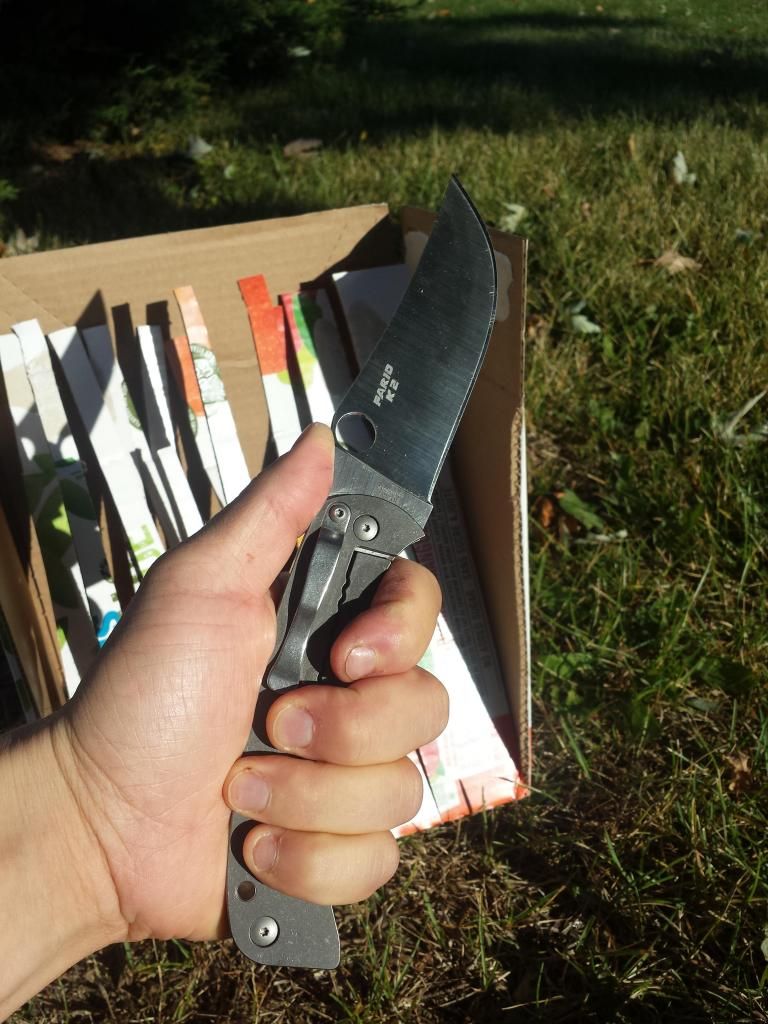

The knife is big, and as such I didn't expect it to fit perfectly in my hand. It's not either, but the knife being thin and wide it gives a good solid hold on the knife without really having pressure point. The only reason I say it's not perfect is that I can't find yet a hold that give me good control over the tip when trying to make precision cut. It did feel really safe in my hand wheter I was cutting cardboard or wood. I'm not used to a knife with that much belly so maybe I'll get aquainted with the knife and soon be able to do those precision cut I'm not able to do yet. Here is a few shoot in hand, both left and right hand. Today is the first sunny day since I got it so those are the first clean looking picture I could get.

Carry:

I'm not going to carry this big knife as much as I'd like simply because I know what kind of reaction I'm gonna get from strangers. It could easily net you trouble if you hold this knife out in public unless for defensive or working purpose. On the other hand, I didn't find the knife to bother me at all when carrying it. It's light and thin, the clip keep the knife in place in my front pocket and is easy to put/pull it from the pocket itself. It does on the other hand take up much pocket space and might be slightly annoying if you have to get your hand in your pocket, at least with my type of pants. I'd vote against trying to carry this knife in a pocket positioned at knee/slightly above knee height.

Cutting ability (**** you Cliff for bringing me deeper in being a knife nut!) and edge retention - Factory retail edge:

The edge out of the box was the sharpest yet. It would cleanly shave arm hair without having to do more then 2 light pass. My MT18 was the next closest with somewhere about 4 to 5 pass to get a clean arm shave. There's no way the K2 would shave beard with factory edge. I tried, it didn't work and got close to cut myself. What I found weird is that even it was the best arm shaver factory edge I got, it would slice printer but only with a small snag once every 2-3 cut. There might be something about grit finish, metal carbide, thickness behing the edge or anything and I'm not going to pretend I know what caused it. It simply happened.

I'm not the type who love low/medium grit finish and as such I usually sharpen the edge before my first use. It ain't because polished cuts better or not, but simply for the grabby feeling when slicing that I don't like from low grit sharpening. Since this knife had great test result from Farid post, that it was shaving cleanly and seriously was the best factory edge I saw, I decided to test it to see what low grit factory finish was able off. Maybe it will turn me from polishing my edge, I'm not against changing my habits if it means better results!

First thing I did was wack down a few cardboard box I saved for the knife as I knew I would get it soon. I cutted about 150 feet of light duty and clean cardboard. You can see the type of box I cutted in some of the upper picture so I won't double post them. At that time, the knife would still shave arm but needed 3 to 4 pass to shave cleanly. Printer paper slicing was unchanged.

I then proceeded to cut some cardbord tube about 3/16 thick I had simply to compare with what farid did. It cutted well and torn away about 50 feet of it before getting bored of this test. The tube was only 1.5inch wide per about 7'6" high so pieces were also getting small and dangerous to cut lol! At this stage I completely forgot to shave test and went straight to wood whittling. We had 2 leaves rake with wooden stick that I needed to shorten for my 4 and 7 years old kid so I gave it a go with my K2 instead of getting the saw out. Being that we saw many discussion saying it can be chippy (Cliff opinion at least) I took care not to twist the knife while cutting to avoid chipping. It took care of the 2 wooden stick without too much effort but I clearly didn't appreciate the low grit for the "carving" type of work I was making.

I must warn people how are gonna push hard on the blade using the other hand thumb to push/control the spine of the knife. The flat of the spine have semi sharp corners that gave me 2 slight cuts. You'd better either wear anti-cut gloves if doing so or give it a quick few sandpaper pass to remove the bite it has. All it took was 20 second with 1000 grit sandpaper and light pressure not to ruin the look of the flat but only take down the "edge" bite.

When I tried shaving test it failed to even cut any arm hair at all under high pressure. It wouldn't slice printer paper without snagging at least once per sheet lenght slice, and most of the time simply tearing it appart. At that point the edge was degraded more then I usually let go any knife and felt ready to sharpen it the way I like it. Then I realized that wood whittling didn't chip the edge at all like expected from Cliff post, but acted more like Jim, Farid and other said it would, at least concerning how chippy it was. On the other hand, I felt it lost it edge way quicker then what we saw from other (way more experienced) testers. So I decided to push that chip test somewhat further, without going into deep abuse, since I didn't care for the edge anymore before I sharpened it.

I decided to do a light bushcraft type of work with the K2 and trimmed down a decorative tree that is growing out of control and that I don't know what to do with. I slashed 40 to 50 small 1/4" to 1/2" sized branches and many hundred smaller without seeing any chip on the edge. It did perform better then I though but since it's clearly not how I'm gonna use it I didn't risk going harder and further.

Sharpening :

So I'm now in the process of thinning the edge somewhat so the bevel will be about 2.5 time the length of the factory one. Reprofiling isn't as bad as I though it would be. Low grit stone can remove much metal even if it wear my cheap stone fast. The trouble reside for me in making it mirror. Polishing it is a real chore and am not done yet on one side but things are getting close. Brings me to think what Cliff said about carbide getting torn out by bigger abbrasive might be right and that high grit abbrasive have a hard time abbrading the carbides. Even my Fiber optic diamond lapping film couldn't remove much metal. Oil would only start to visually grey out from containing metal residue after 30+ pass with the 3um grit diamond lapping film and would take more then 150 to see some with the 0.5um film. Will update on cutting ability and edge retention when I'm done sharpening/testing somewhere next week.

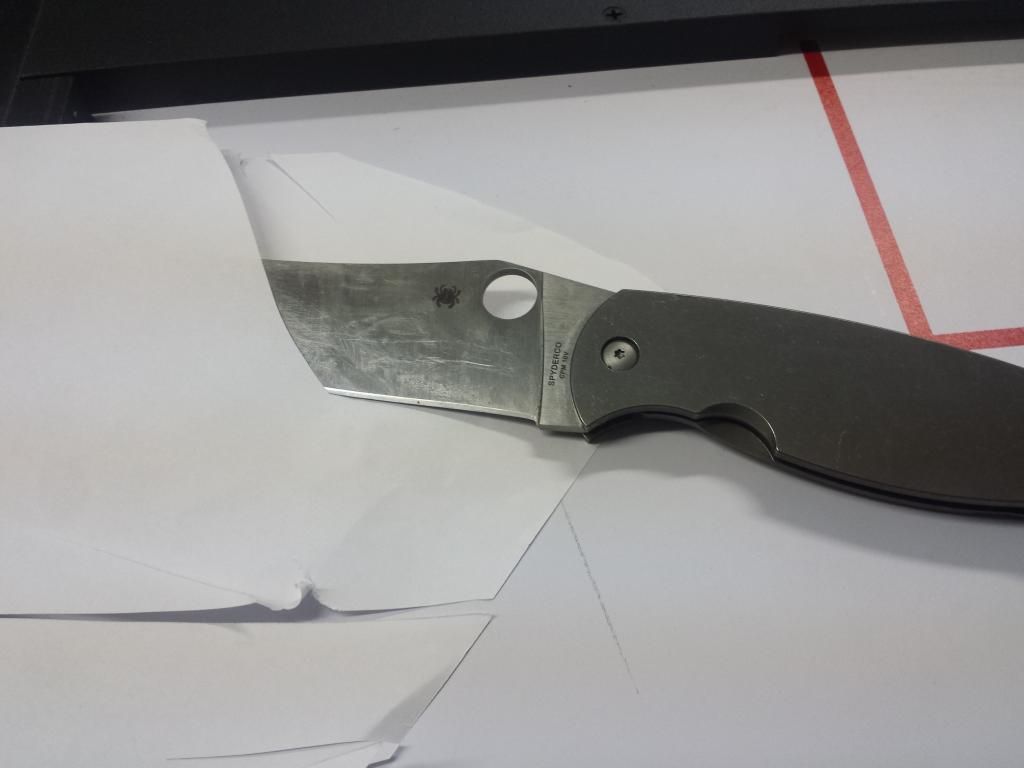

Semi-mirror candy pic:

To show the difference, I went and did a test. Cleaned the diamond film perfectly. I then made 45 pass on the 3um diamond film (3/4" wide x 6" long), saw a really slight metal reflect in it and took a picture. I made more pass until the metal was easier to see in the oil. I stopped at 105 pass. I cleaned the film again and made a few pass on the Superblue (30 pass exactly). I took care to go on superblue after and not before so people can't say the film is used and have less cutting power. It wasn't anywhere like new when used on the 10V, but things were even worse on the SB but still removed way more metal.

45 pass on 10V(hard to see metal hue):

Comparison of Superblue Stretch, 30 pass on 3um diamond film vs 105 pass on 10V:

I will say again this is only regarding higher grit sharpening. Using low grit, cheap abbrasive stone the metal removal rate wasn't bad at all and I think is within reach of anyone who's willing to take a few minutes to get things done right. If you look at how much metal I removed before polishing one side of the edge (took about 20 minutes total for metal removeal with poor stone and average or below average sharpening skills, 45minutes if including the hand polishing), you'll understand that sharpening only the edge would be a quick thing, even quicker if not polishing it. Initial bevel was 0.95mm to 1.10mm high, and is now 1.85mm to 2.10mm high. I guess 2-3 minutes would make a great polished micro-bevel.

Cutting ability and edge retention - Thinned edge:

I lowered bevel angle to about 8.5dps as I explained in one of the post, polished it and followed by putting a micro bevel of about 12.5-13dps on it using a home made tool similar to the edge pro. Since I don't like toothy edge (that's only because it's how I like my edge, not impliying low grit couldn't do better) I used 3um diamond lapping pad for the micro followed by 2-3 pass of 0.5um diamond pad too. At first I was thinking about using this razor sharp edge for a comparison run versus my SB stretch with similar bevel/micro-bevel angle. But things got out of control as I went in the woods with my kids and couldn't resign myself not to use my K2. We found some thick vine growing to the top of a few tree that the kids wanted to use as "Tarzan rope" so I took my K2 out and started to hack the vine. In our quest for the best Tarzan rope, I cutted a total of 9 vine with a diameter of about 1.5" up to 3" for the biggest. Most were 1.5" to 2", with only 2 in the 3" size range. The 3" took a few minutes to cut, hacking it down mostly. I can say the kids had a great deal of fun!

It's not the hardest type of wood, but I wasn't going gentle with the knife. It held up very well, and even more then I had expected! When I got home I checked sharpness and it would still slice printer paper and cleanly shave in 3-4 medium pressure pass.

The tear in the paper was made from testing sharpness before setting the micro.

Really impressive to say the least. Since there's now way to directly compare it to another knife with this use, I'll reset the edge and run a comparison test later. The only sure thing is that from my little experience with knife, I feel this one is the first I own to have such great edge holding ability.

Overall impression:

Farid and Sal did a great job on this knife. Flicking this beast out is addictive, even for someone like me that never was into flicking. It makes you feel special holding such a knife. I did feel like edge performance were not on par with Farid test being both knife had factory edge, but on the other hand this thing fared better then any other knife I tried yet so I guess the sharpening I'm doing will bring performance up by much for my type of use. It must be made clear that the sticky lock on my specimen slightly got better over time but isn't perfect yet. As I stayed on another thread, watch out trying to one hand close it if the lock is sticky. It'll bite you!

I say don't miss this great opportunity to own one of the most awesome knife out there!

Congrats to the makers!

Link to post about further use of the knife:

More about sharpening

More about use around the house

More about clip position and carry

More about corrosion resistance of the 10V