ZDP-189 - choosing the right waterstone

Re: ZDP-189 - choosing the right waterstone

OK, I understand your point. You lack a point of reference for speed and hardness of a stone.

First of all - you do not want a stone that get's described as 'soft and muddy'. Soft and muddy is great for leaving less scratches and better feel during sharpening (yes, we kitchen knives nuts do like that :D ), but will dish fast and produce a lot of mud. You do not want a lot of mud around the pivot of your pocket knife. So you are looking for a hard stone. The JNS300 is probably one of the hardest stones - maybe only short of Norton glass stones (I am guessing here).

Speed - you are going to be working on a small (tiny would be a better word I guess) blade. All decent coarse stones will get the job done in some 10 - 15 minutes. It may take longer if your are not experienced. Diamond stone will be faster - no doubt. But coarse diamond stones will leave deeper scratches which you may not enjoy on your bevels or do not want to spend too much time removing with finer stones.

Once you set the bevel with coarse stone you may want to use finer stone (1000 - 2000) to get it look nicer, before you switch to sharpmaker for the cutting edge.

Does this help?

First of all - you do not want a stone that get's described as 'soft and muddy'. Soft and muddy is great for leaving less scratches and better feel during sharpening (yes, we kitchen knives nuts do like that :D ), but will dish fast and produce a lot of mud. You do not want a lot of mud around the pivot of your pocket knife. So you are looking for a hard stone. The JNS300 is probably one of the hardest stones - maybe only short of Norton glass stones (I am guessing here).

Speed - you are going to be working on a small (tiny would be a better word I guess) blade. All decent coarse stones will get the job done in some 10 - 15 minutes. It may take longer if your are not experienced. Diamond stone will be faster - no doubt. But coarse diamond stones will leave deeper scratches which you may not enjoy on your bevels or do not want to spend too much time removing with finer stones.

Once you set the bevel with coarse stone you may want to use finer stone (1000 - 2000) to get it look nicer, before you switch to sharpmaker for the cutting edge.

Does this help?

... I like weird

...

...

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

No, I have lots of references :Matus wrote:OK, I understand your point. You lack a point of reference for speed and hardness of a stone.

That is just a sample of some the stones I have in the medium coarse range. I also have a bunch of naturals and various synthetics. My point is the above is that commentary on stones usually lacks references so what is described can't be interpreted.

For example if I tell you that I have used a traditional Ghiro stone which is soft then what does that mean? If I am comparing it to a Spyderco fine ceramic stone then soft means something very different than if I am comparing it to a Naniwa Aotoshi 2000. If I don't say that I am referencing then you can't really tell anything at all, but almost no one notes these references.

To clarify I have lots of stones, I am just looking for ways to describe them so that it is meaningful. In regards to hard vs soft, which one I would pick to use depends mainly on the steel and how much force I am going to apply.So you are looking for a hard stone.

The Naniwa Superstone 400 is very nice for grinding ZDP-189, however the Bester 700 is much better for grinding VG-10. Why, because the Bester 700 will easily chip the ZDP-189 but the Naniwa will not. Neither will chip the VG-10 significantly as it is much lower carbide than ZDP-189 and significantly softer so the apex is tougher in multiple respects. However neither of them are optimal for grinding very easy to cut steels like say L6/56-58 HRC which is so easy to cut then a very hard stone like the Suehiro Chemical is more optimal because the steel is so easy to grind then you don't need an aggressive stone but a stone which resists flattening is more optimal.

Now I know this because I have used all of those stone on all of those steels in great detail in multiple cross comparisons. But the question isn't what do I know, that is easy, all you have to do to know is just do the work and I really have no problem with that. But how do I communicate this to someone else who wants to know the answer to a simple question "Hey, what do I buy, the Naniwa Superstone 400 or the Bester 700?" . I am still working out how to compare stones in a meaningful way to allow answering a question like that as easy as it is to answer a question like "Hey, which steel should I use, D2 or O1?" . That is easy because it is easy to compare those steels in a meaningful way that anyone can understand.

Re: ZDP-189 - choosing the right waterstone

Very interesting study. Thanx for the input. Keep us posted.

sal

sal

Re: ZDP-189 - choosing the right waterstone

I see, you are actually not actually looking for an advice, you are trying to educate us

Seriously - you make a valid point. It is very hard to convey with words how does given stone work on given steel. Since you have made it this far (experience with many stones and steels) - you could really profit from talking to Jon from JKI (I did 2 or 3 times over the time - once it was a 1 hour long discussion over Skype) - he's not only extremely knowledgeable on the topic, he is also really nice guy to talk to.

Seriously - you make a valid point. It is very hard to convey with words how does given stone work on given steel. Since you have made it this far (experience with many stones and steels) - you could really profit from talking to Jon from JKI (I did 2 or 3 times over the time - once it was a 1 hour long discussion over Skype) - he's not only extremely knowledgeable on the topic, he is also really nice guy to talk to.

... I like weird

...

...

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

That is the problem, until I figure that out I can't communicate about it in a meaningful way and to me that is a large part of what I enjoy about working with knives and more lately stones is discussing them. It is not impossible however it just has to be worked out. For example in this thread http://www.cliffstamp.com/knives/forum/read.php?7,34846" target="_blank C Amber argues that hardness of a stone is really a mix of different properties and after some back and forth it is clear that instead of talking about if a stone is hard or not it is more precise and accurate to talk about if a stone has gouge resistance and the rate of wear. It is possible for a stone to have both of those, none of those or one or the other. But if I just say it is hard or soft you can't tell.Matus wrote:It is very hard to convey with words how does given stone work on given steel.

I have talked to Jon, however we have very different perspectives on sharpening to such an extent that his perspectives on abrasives isn't significantly useful to me. He is a proponent of heavy burr based sharpening for example. I see that as not only being pointless but simply wasteful, and similar I don't hold the same views he does on steels, strops, etc. . Stu from Tools from Japan has a very wide experience with stones, has done large scale comparisons and in general provides a lot of frank information. When I recently ordered some stones from him we discussed what I was looking for and he argued I should not actually buy most of the stones I was looking at as they would not work and suggested a much smaller and less costly set of stones. I bought pretty much the full set anyway as I was curious, but on each stone I have used so far his descriptions are fairly accurate.... you could really profit from talking to Jon from JKI (I did 2 or 3 times over the time - once it was a 1 hour long discussion over Skype)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Thanks Sal. The thing to me which is of most interest is how a stone can work not very well on one steel but very well on another, so much so it really changes how you view if a steel is easy/difficult to sharpen.sal wrote:Very interesting study.

Re: ZDP-189 - choosing the right waterstone

Cliff, I did not realise the extend of your experience with different stones when I entered this discussion. Obviously your interested and expectations go way beyond that most users ever try to learn or reach (that includes me, honestly). Still - should you find the right stone for ZDP please let us know, I believe many may find that information valuable (in particular when it comes from somebody with so much experience).

... I like weird

...

...

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

No worries, the first thing I have to do is figure out what that question means before I can figure out how to answer it. I would be confident enough now to say I think such a question can be answered but I am still in the process of setting out the matrix by which to evaluate it. But I have lots of knives to sharpen for friends/family anyway who are all hillbillies and chew up knives on a regular basis so I get to do a lot of shaping as well as apex setting. At this stage I am comfortable making some basic statements but it is pretty easy to ask a question which I can't answer such as "At what pressure and carbide level do the Sigma Power II stones become more efficient than the Bester stones?" . I know there is a transition, I know both are a waste on steels like L6/56-68 HRC, I know the SPS-II stones work much better on the ultra-hard and ultra-high carbide steels but where exactly is that cut off. But not knowing just means something to learn and that is the fun part.Matus wrote:Still - should you find the right stone for ZDP please let us know ...

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: ZDP-189 - choosing the right waterstone

I saw this thread when it was posted. For one reason or another I didn't read it but saved it. When I first got a ZDP-189 knife (Michael Walker sprint) I could NOT sharpen it at all. I didn't know why and still I'm not sure why. Probably several reasons first being a lack of skill. Also, I don't remember what type of stones I was using. I THINK I was using the EP with the standard EP stones. I wouldn't swear to it though. Recently I got another Michael Walker from an unbelievably generous person. I also recently got a Caly 3 (CF/ZDP-189). Now these two knives (and Manbug ZDP) are as sharp as I can get any knife with any blade steel. After using a very small variety of stones over the past 5 years or so I've settled to a set of DMT, Shapton glass and Spyderco (F & UF). So, these are what I've used on the MW and Caly since I've had them (6 months or less). Another problem I've had has been getting a super sharp edge when using the Shapton glass stones. I would routinely use the Shapton glass up to 8k and then use one or both of the Spyderco stones to finish the edge if I wanted the super sharp edge. As super sharp as I can get them that is. Recently I'm getting the super sharp edge using only the Shapton glass stones. The inability at getting the super sharp edge with the Shapton's applies to all steels I used. I'm starting to confuse myself in trying to explain what I'm thinking so let me just say I believe Shapton glass stones do a great job on ZDP. This is a somewhat older thread and maybe you got the answer you were looking for. But maybe not. As has been mentioned, it's hard to explain my impressions so someone else will understand. Also, good vs bad, fast vs slow, are normally a comparison more than a measurement. We have a thermometer to describe the temperature outside. When I say 50 degrees most people know what I mean. We have no thermometer to use as a reference for stones.Matus wrote:Cliff, I did not realise the extend of your experience with different stones when I entered this discussion. Obviously your interested and expectations go way beyond that most users ever try to learn or reach (that includes me, honestly). Still - should you find the right stone for ZDP please let us know, I believe many may find that information valuable (in particular when it comes from somebody with so much experience).

So what I think I'm trying to say is I believe Shapton glass stones are good for ZDP. Also, the ceramic Spyderco stones are great for finishing ZDP if you have used other coarser stones up to about 2k or so. I've also been learning to hone straight razors for 1.5 years now. The Shapton glass stones up to 16k is a good set according to Lynn Abrams (Straight Razor Designs). I have been using them but I have no experience to say whether they are good or bad compared to other stones. The Naniwa super stones seem to also be respected by razor honers. Since a straight razor needs to have a very smooth edge apex (NOT :eek: toothy) it seems the stones better for them would be more like the Naniwa Aotoshi 2000 Cliff mentions. I was considering the Naniwa 12k stone for straight razors a few months ago and emailed Lynn about it. He replied back that since I already had the Shaptons the Naniwa wouldn't get me any better results than what I already have. His reply also said (knowing I was a beginner) that any lack in sharpness was going to be corrected with technique improvement. Without good technique not many tools will give us the results we desire.

One thing I will try to emphasize is how much I respect the ceramic stones from Spyderco for finishing an edge. Every single time I don't use them for a while and then use them again I'm re-impressed. I am getting very good results going from a Shapton 8k to the Spyderco UF stone on straight razors. Again, I'm a beginner with razors so my opinion even I don't consider to be written in stone. So many of my beliefs about sharpening in general have changed over the last few years I now am very hesitant to state something as "fact". It's just what I think I think at the moment (I think :) ).

I still have never used a stone that creates a lot of slurry when sharpening or by using a slurry stone. At the moment I'm not into buying more sharpening stuff but I'm sure the itch will hit me again. When it does I think it will mean it's time to try a couple of Naniwa's. When trying new stones I think I like having more than one of that type. How a diamond stone finish is changed by a different type of stone is harder to determine or learn than using the same type stones it seems to me. This is just one of those things that experience means a lot. Experience that I don't have.

Final comment about ZDP and my recent success. Maybe my technique is better now than 4 years ago. Maybe I'm using the proper stones for ZDP now. It's hard to know for sure because I know my technique is better but don't know how much difference that makes. It's also hard to know because I don't know what stones I was using 4 years ago. The only thing I do know is I can get ZDP as sharp as any steel I've used now and I couldn't do that until the last 6-8 months or so. I know my technique is better and I know I'm using Shapton glass stones and I know my ZDP edges rival that of any other steel I'm familiar with. So take that for what it's worth. One comment about the Shapton glass stones. It took a LONG time for me to be able to get great (for me) results with them. I would always use the Spyderco fine and/or UF stones after the Shaptons. Now I'm getting edges just as sharp off just the Shaptons as I do off the Spyderco stones.

I don't know if this helps but I hope it does.

Jack

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Really curious how the glass stones compare to other waterstones you have used. I really like the idea of thinner waterstones, especially in the finer grits because the very slow rate of wear means those ~1" thick ones are kind of wasteful.jackknifeh wrote:After using a very small variety of stones over the past 5 years or so I've settled to a set of DMT, Shapton glass and Spyderco (F & UF).

-

can't freehand

- Member

- Posts: 160

- Joined: Thu Jan 01, 2015 4:19 pm

Re: ZDP-189 - choosing the right waterstone

Then why not use DMT diamond stones for ZDP-189? Different abrasives for different 'applications', certainly, and also if we're hobbyists, but do Waterstones offer any significant advantage over diamond for ultra-sophisticated alloys like ZDP-189? Diamond abrasion is by nature more aggressive, or coarser, I think, and doesn't that pronounce carbide content whereas the super-fine nature of these super waterstones would homogenize the carbide with the surrounding matrix?Cliff Stamp wrote:

An obvious solution to sharpening ZDP-189 and similar high carbide steels is to retreat to a more coarse stone and use the Sharpmaker to micro-bevel after grinding a large relief bevel on a new blade. But while a lot of stones are decent for a lot of knives, some stones will not work well on steels like ZDP-189, yes they will grind the steel but the edge will not form clean.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

One thing to realize is that there is a tremendous amount of distortion about steels like ZDP-189 and 10V as if it is a modern idea to have very high carbon/carbide content. This type of steel is very old, D7 and T15 for example. T15 has a higher wear resistance than M4, a massive carbide content in a high cobalt-HSS. Not only is this type of steel old so are the abrasives to sharpen them. It is one of the odd things in the knife industry that the idea that carbides in steels is some kind of new idea or even that it is inherent to steels. For example cast irons have massive carbide volumes which is why they are used in rollers.can't freehand wrote:... but do Waterstones offer any significant advantage over diamond for ultra-sophisticated alloys like ZDP-189?

In any case, it is critical question - why use waterstones on steels like ZDP-189 when waterstones typically use alumina and diamond would seem to be more suitable to cut high hardness and high carbide steels. The carbides in many of the high wear steels can in fact be harder than alumina but they are all butter soft compared to diamond. Even vanadium carbide might as well be chocolate pudding when it comes in contact with diamond. I didn't hold this position a few years ago and would have said to use diamond, I mainly changed my position after extensive work with a Naniwa Superstone 400 and then verified the results with other similar stones (King 1000 for example).

The first thing is that you have to realize that very basically sharpening consistent of two very distinct steps :

-rough grinding, just removing metal

-setting the finish of the apex

The big problem most people have is mangling two of these together, often trying to do them at the same time. But they are very different in goal and thus the stones that do them well are very different. In some detail, here is a typical sharpening on a dull blade :

-Suehiro 'Chemical' 320, rough grinding, remove any damage to the edge bevel, thin if necessary, bring the edge close to an apex

What is required here is just a fast cutting coarse stone. I like the Suehiro as it is inexpensive, tolerates high pressure decently well, holds water and can be used with just a light spray if it was soaked the previous day. A coarse diamond stone or oil stone also works well here. For very high pressure grinding the Norton India and Crystolon are even better then the Suehiro.

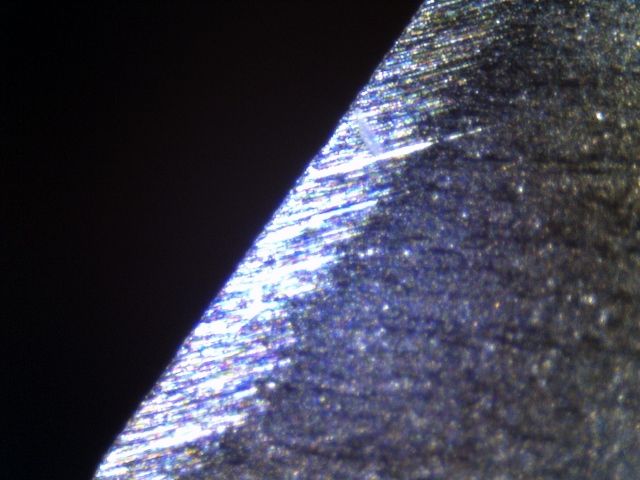

-Naniwa Superstone 400, bring the edge very close to an apex

This is where the nature of the stone comes into play. The Naniwa forms a very light silty slurry and this very fine mud ploughs into the apex of the edge as you grind and it removes any burr/damage and it allows you to generate a decent level of sharpness with no burr and no real attempt/technique to minimize a burr, it just happens naturally.

-Soft arkansas, Spyderco Medium, MXF DMT, 1200 Atoma, set the apex bevel

These stones are all very hard, do not breakdown much (almost none in some cases) in use so the apex isn't ploughing through anything and thus they leave it with very thin < 1 micron. This bring out high sharpness easily.

Now can you sharpen with reversing the stones? Can you grind an edge without a burr using the 1200 Atoma or set an apex with the Naniwa Superstone? Sure, anything is possible but you are basically trying to peel potatoes with a Spyderco Tuff. The knife looks horrible because it is being used in an area almost opposite where it was designed to excel. Similar, trying to grind an edge with a Norton Crystolon and avoid a burr is much harder than with the Naniwa Superstone which does it by design.

Re: ZDP-189 - choosing the right waterstone

I had some good results using the edgepro with edge pro stones using light pressure to avoid forming a burr and going from the 600 grit and then straight to the polishing tapes with a ZDP-189 caly 3.5 and a Delica in ZDP. I used 2 bevel angles with the actual edge bevel being quite small and 18 dps minus the angle of the full flat (I believe 2.5 or 2.25 dps on those knives, I measured with angle cube but it's been a while, the 3.5 is a little steeper than the Delica iirc).

I found it I used the lower grits a burr would form consistently and the more steps I used on the actual edge with the ZDP the less durable and wear resistant the edge seemed. That seems to conform with the opinion that forces on the very edge fatigue the metal and lead to premature failure.

Another thing I've been doing lately is EDCing 2 Delica 4s, one in ZDP one in VG10 and seeing if anything dramatic enough to be noticeable in an anecdotal non scientific setting happens in everyday use and sharpening/maintenance.

Thus far it hasn't really happened, and it's pushing me towards believing the differences in steel performance in cutlery is small enough to require pretty tight controls to draw any valid conclusions.

I found it I used the lower grits a burr would form consistently and the more steps I used on the actual edge with the ZDP the less durable and wear resistant the edge seemed. That seems to conform with the opinion that forces on the very edge fatigue the metal and lead to premature failure.

Another thing I've been doing lately is EDCing 2 Delica 4s, one in ZDP one in VG10 and seeing if anything dramatic enough to be noticeable in an anecdotal non scientific setting happens in everyday use and sharpening/maintenance.

Thus far it hasn't really happened, and it's pushing me towards believing the differences in steel performance in cutlery is small enough to require pretty tight controls to draw any valid conclusions.

Re: ZDP-189 - choosing the right waterstone

Maybe I missed it but there was no defining of the carbides and their hardness?

ZDP-189 is a hard and carbide rich steel but they are Chromium carbides which only run into the upper 60's of Rockwell hardness. Even the low abrasive density King waterstones can sharpen ZDP it's just going to take longer than if you were using Shaptons.

ZDP-189 is a hard and carbide rich steel but they are Chromium carbides which only run into the upper 60's of Rockwell hardness. Even the low abrasive density King waterstones can sharpen ZDP it's just going to take longer than if you were using Shaptons.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: ZDP-189 - choosing the right waterstone

The only other water stones I've used are the ones that came with the Edge Pro that I bought 4-5 years ago. When I decided to upgrade those stones I went straight to the Shapton glass. Then when I wanted to buy water stones for free hand sharpening I got the glass stones. So I don't have much experience with different water stones. But the difference in the EP water stones and the glass is significant. The EP stones wear much faster than the glass. Also, the EP stones ALWAYS would leave little random scratches deeper than the rest of the scratch pattern of the given grit. This became very noticeable when using the higher grits. The higher quality water stones probably don't have this problem. I'm sure I lost a lot of learning but when I decided to start using water stones I wanted to use what the very experienced considered one of the better stones. The same guys that praise Shapton glass also praise many other water stones but everyone seemed to like the glass stones so I got them. Anyway I don't know about other water stones especially in regard to ZDP. If anyone is looking to buy stones for steels like ZDP and other harder ones it seems, from my limited experience, the Shapton glass are a good choice. Also, since they are more expensive than some other stones keep in mind you don't need every grit. In the bench stones I have 320, 500, 1k, 2k, 4k, 8k and 16k. I bought them over time and two of them (500 & 2k) I got just because I wanted a complete set. I was getting superb results going from 320 to 1k to 4k to 8k. If anyone is considering these stones I'd recommend starting with the 1k and 4k. I haven't done a lot of experimenting but it seems the Shapton glass stones do well jumping from a 1k to 8k with good results. Murray Carter uses the King Japanese water stones in the 1k and 6k grits and that's all. Another thing about his demonstrations is he says to not need to flatten stones as often is to focus the contact points of blade to stone on the corners and any areas you don't normally touch with the knife edge. As long as you keep the angle where you need it, that's all that matters. But, when you are talking about the different skill level between Murray and the average guy, this is easier said than done. I do hate to wash stone down the drain just to keep the thing flat though. One thing about flattening the higher grits though is the finish is better when the stones are very clean. I noticed this when honing razors. I only got the 16k when I started on straight razors. I don't think a 16k stone is needed at all for any EDC knife. In fact anything over 2k is "just for fun" IMO. :) The higher grits may be needed for specific cutting needs but for an EDC knife that you will usually be using for no telling what 2k is probably as high a grit as we need. Just my opinion, NOT fact. :)Cliff Stamp wrote:Really curious how the glass stones compare to other waterstones you have used. I really like the idea of thinner waterstones, especially in the finer grits because the very slow rate of wear means those ~1" thick ones are kind of wasteful.jackknifeh wrote:After using a very small variety of stones over the past 5 years or so I've settled to a set of DMT, Shapton glass and Spyderco (F & UF).

Another thing about sharpening ZDP-189 and other harder steels is I THINK they require a higher level of ability than the other steels like VG-10, S30V, etc. I have that opinion because I'm getting better results (sharper) on ZDP than I used to and I know my technique has improved. But my poorer results before may have been not using the best stones for ZDP. I really don't know. Something to consider and also I'd like to hear other opinions on that. The significance of this MIGHT be that if someone who is a very skilled sharpener and also has the proper stones can try sharpening ZDP for the first time and have great results. That person won't understand why others have trouble. Sitting here right now I can't put my finger on why I had TERRIBLE results when first sharpening ZDP. Low skill level or incorrect stones or both. Since I did have problems the thought in the title about having the proper stones struck a cord with me. If anyone wants to sharpen ZDP and doesn't have stones they know will do the job I recommend getting stones that others have success with. Then, if the results aren't as good as you want you can be assured it's probably your ability and that can be corrected with practice. Very soon the edges will be very sharp. But if you don't have "known" ZDP sharpenable stones you won't know what the problem is.

I know I'm starting to ramble.

About the Shapton glass vs diamond stones. I think if I were looking to buy one or the other I'd get the Shaptons. I don't say that because of ZDP only. I say it because I know the Shaptons work on anything I've sharpened including ZDP and I perfer them (personal preference is all) to diamond stones. But I take sharpening as a hobby in addition to just getting my knife sharp. That makes a big difference. Most people don't want a complete set of Shaptons, DMT and Spyderco stones. First of all that's a lot of money. Also, for sharpening to be a hobby it means a lot more time than most people want to spend on sharpening knives. These are probably very wise people. :D I think diamond stones will sharpen ZDP just fine. I'm going to test that statement to see. I'm going to dull a ZDP blade then see the results using the DMT stones. I'll judge the edge after the fine grit and then the extra-fine grit. I don't know how accurate my "test" will be as I don't have any advanced equipment like magnification tools. I will judge by how the edge slices phone book paper and the sound I hear as the edge slices. The quieter, the sharper. Then also the edge cutting into the top of the sheet with no slicing. When the edge is truely sharp the edge will "fall" into the paper if the knife is not a very small, light knife. I'll do this test (DMT vs Shapton) with my Caly3.

There are other steels that will hold an edge as long as ZDP or close enough that it doesn't really matter when talking about an EDC knife. M4 for example. And M4 seems to be a lot easier to get the super crisp edge on than ZDP. I was getting M4 super sharp (for me) even when I was still having problems with ZDP. So, if anyone is wanting to buy stones that will sharpen everything including ZDP wait until after I do this DMT vs Shapton test. I think both will do a great job so either would be a good purchase. But I'm interested in what I'll find with this test. But don't base your decision only on what I say. I'll state my opinion while admitting my opinion has changed several times about various things regarding sharpening over the last 5 years. So my opinion today may be different in a year. On several occasions I've stated my belief only after more experience found that belief was only partially correct or even completely wrong. So take that into consideration when putting a value on what I say.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

If I asked you what was the hardness of steel then how would you answer? It is likely you would think it is a strange question because steel doesn't really have a hardness. It depends on how it is processed and the type of steel. It can either be really hard (70 HRC) or so soft you can't even measure it on the HRC scale.Jason B. wrote: ZDP-189 is a hard and carbide rich steel but they are Chromium carbides which only run into the upper 60's of Rockwell hardness.

Chromium carbides are similar in that there are different types and that the types are often made of different elements. A chromium carbide isn't made out of just chromium. If there is vanadium in the steel for example it will dissolve into the chromium carbide and make harder by solid solution strengthening.

The two main forms of chromium carbide in steels are Cr7C3 and Cr23C6. Cr23C6 has a hardness from 900 to 1400 HV, Cr7C3 ranges from 1300 to 1800 HV. These are much too hard to produce HRC readings. As they get solid solution strengthened the hardness moves up into the 2000 HV range.

However, even in high carbide steels, most of the material is just steel which is why you can sharpen even something like 10V with an Arkansas stone.

The difference in these stones isn't the abrasive density, it is the bond strength. Kings use a very weak resin bond and they release abrasive very readily and thus you get slow abrasion because higher pressures are not productive and you get mainly 3-body (rolling) type wear. They are best used for very low pressure grinding where you want blending/random abrasion. They are great for that, very similar to the Naniwa Superstones.Even the low abrasive density King waterstones can sharpen ZDP it's just going to take longer than if you were using Shaptons.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

Jack,

Thanks for the detail, how often do you flatten the Shapton Glass stones?

Thanks for the detail, how often do you flatten the Shapton Glass stones?

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: ZDP-189 - choosing the right waterstone

I flatten them every time prior to honing a straight razor. Normally, I'll only use the 8k as a refresher stone then the Spyderco UF then strop. If the razor needs more work I'll go as far down as the 1k. But for razors I flatten them every time. This is to have a flat, clean stone because the edge on the razor will be scraping my face. :) I want it as clean and smooth as I can get it. For knives I may flatten them every 10 knives or so. I don't flatten them to keep them flat. I flatten them more to have fresh, clean stone. I don't think the "flatness" is as important. Some have stated that when a stone isn't flat the angle on the edge can change as the knife blade is traveling along a stone with curvature to it. While I understand this and agree in principle that thought is assuming I can hold the blade at a perfect angle. I think the angle on a perfectly flat stone will change throughout a single stroke more because of my inaccuracy than because of the curvature in a non-flat stone. If the curvature (dishing) on a stone is bad enough to significantly effect the angle ground on the edge that stone is definately in need of flattening. I would never let a stone get that flat. I also used the Shapton glass stones on the EP and they required flattening MUCH less than the water stones that came with the EP. With a 1" wide stone and the way I used the EP the wear was more toward the center of the stone. When I free hand I can control where the blade edge touches the stone and I spread out the path during a stroke. By default my stroke path is evident by the mark on the white stone is from the bottom right side curving toward the middle of the stone and then traveling back toward the right corner at the top of the stone. This is when I use my right hand. When I stroke the other side I use my left hand and the path is the same, just reversed. Since I can see the path I will intentionally alter it so the marks appear only in the center or along the side. I try to use as much of the surface as I can to keep it as flat as I can when sharpening the stone instead of washing it down the drain. Later today, when I do the Shapton vs dmt stones I'll get them clean and take pictures of this "stroke path". Pictures may make it more clear. I do like the fact that the Shaptons are almost white. It makes seeing the stroke path and how much steel is being removed much easier.Cliff Stamp wrote:Jack,

Thanks for the detail, how often do you flatten the Shapton Glass stones?

Jack

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: ZDP-189 - choosing the right waterstone

What do you use to flatten them and how long (just roughly) does it take?

Re: ZDP-189 - choosing the right waterstone

:p darn clear in mind but muddle in writing...

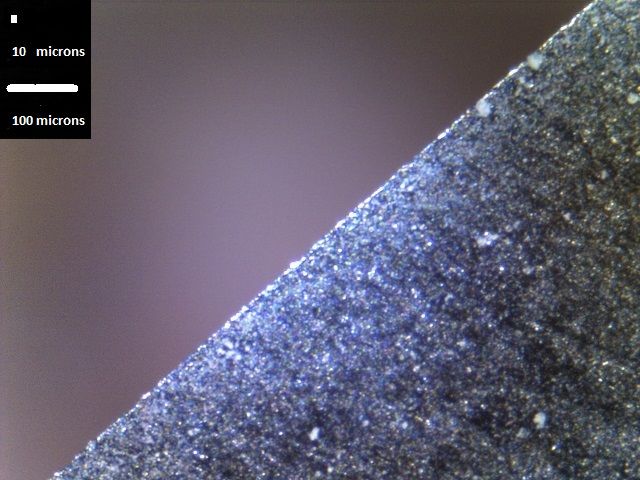

ZDP-189 high carbide volume has narrow matrix(much softer than carbide) spacing between hard particles (mostly Cr carbides). Simplified view of surface/edge shaping be combination of - fast to slow - plow to burnish matrix & carbides.

Use large low-friable sharp fixed abrasive (atleast 3x larger dia than carbide) with high pressure to plough away material. Coarse diamond plate, ceramic belt, hard waterstone (SiC, AlO, ceramic), hard oilstone and including King's New low grit waterstone all are effective for ploughing.

Abrade rate is faster against matrix than carbides, so when abrasive teeth/points shear and roll (2 bodies and 3 bodies wear) easily abrade away matrix and must shape/cut carbides (ok, if the impact dislodge carbides, then it's a plow case) at a slower rate. With high friable (easily fracture) abrasive - e.g. SiC - 2 bodies quickly turn into 3 bodies and at much reduced size. Which can rapidly will slow down the abrading rate. Pressure factor really only at play for fixed-abrasive (e.g. diamond/ceramic plate, etc..). Shapton glass&pro stone uses stronger binder and low friable ceramic abrasive, so it would be more effective than softer alumina waterstone (e.g. King).

* ok, let's skip burnishing size this steel at high hrc is nonconducive to plastic flow. Also skip pressure, substrate type, bevel angle, et... *

When grit size is less than 2x of carbide diameter, abrade carbides you must. Carbides flip thing around, will acts more as plougher than subject. The rate of abrasive release/tear out proportional to substrate binder strength. King watertone will turn into mud with extra fine grit very quickly, sure it probably does some polishing (and minor rounding) but sure ain't abrading much. Shapton Glass (skip Pro now) much harder binder will still be fairly effective. 3um diamond plate works best here. Loose/strop abrasives (diamond, cbn, etc...) could easily result in rounding/wire the edge.

Although it sounds cool & fun to brag about using very coarse SiC/AlO stone and broken-in diamond/ceramic along with low pressure to produce shaving or tree-top edge. Instead I think, we are better off to use right tools for the job... With skills, work around and parlor trick come easy :cool:

ZDP-189 high carbide volume has narrow matrix(much softer than carbide) spacing between hard particles (mostly Cr carbides). Simplified view of surface/edge shaping be combination of - fast to slow - plow to burnish matrix & carbides.

Use large low-friable sharp fixed abrasive (atleast 3x larger dia than carbide) with high pressure to plough away material. Coarse diamond plate, ceramic belt, hard waterstone (SiC, AlO, ceramic), hard oilstone and including King's New low grit waterstone all are effective for ploughing.

Abrade rate is faster against matrix than carbides, so when abrasive teeth/points shear and roll (2 bodies and 3 bodies wear) easily abrade away matrix and must shape/cut carbides (ok, if the impact dislodge carbides, then it's a plow case) at a slower rate. With high friable (easily fracture) abrasive - e.g. SiC - 2 bodies quickly turn into 3 bodies and at much reduced size. Which can rapidly will slow down the abrading rate. Pressure factor really only at play for fixed-abrasive (e.g. diamond/ceramic plate, etc..). Shapton glass&pro stone uses stronger binder and low friable ceramic abrasive, so it would be more effective than softer alumina waterstone (e.g. King).

* ok, let's skip burnishing size this steel at high hrc is nonconducive to plastic flow. Also skip pressure, substrate type, bevel angle, et... *

When grit size is less than 2x of carbide diameter, abrade carbides you must. Carbides flip thing around, will acts more as plougher than subject. The rate of abrasive release/tear out proportional to substrate binder strength. King watertone will turn into mud with extra fine grit very quickly, sure it probably does some polishing (and minor rounding) but sure ain't abrading much. Shapton Glass (skip Pro now) much harder binder will still be fairly effective. 3um diamond plate works best here. Loose/strop abrasives (diamond, cbn, etc...) could easily result in rounding/wire the edge.

Although it sounds cool & fun to brag about using very coarse SiC/AlO stone and broken-in diamond/ceramic along with low pressure to produce shaving or tree-top edge. Instead I think, we are better off to use right tools for the job... With skills, work around and parlor trick come easy :cool: