Can we talk about stones?

Can we talk about stones?

What's up guys. I'm interested in freehand sharpening. It just seems fun and relaxing to me. Not to knock the products out there, as I love the SM, but something about freehanding intrigues me. I've been researching alllll day and I believe I know what to get.

I'm looking into getting the Shapton Glass stone set with 1000, 4000 and 8000. I'm also going to get a DMT D8C for lapping. Is it a good set to start with? Should I get a courser grit like 320 or 500 or can I use the DMT D8C for my rebeveling, harder repair work, etc. as well?

I'm looking into getting the Shapton Glass stone set with 1000, 4000 and 8000. I'm also going to get a DMT D8C for lapping. Is it a good set to start with? Should I get a courser grit like 320 or 500 or can I use the DMT D8C for my rebeveling, harder repair work, etc. as well?

The coarse DMT is my choice for rebeveling and stone flattening. I've got an XC and it is very aggressive. Usually I break that out if I'm really trying to lower the bevel or do some serious repair.

I went with a set of DMTs as my freehand stones XC, C, F, EF and the 6 micron stone. Also had the EEF but I could never get it broken in properly, so I sent it back for the 306UF stone and use that for finishing. I liked the DMTs because they can be used wet and dry with no flattening needed, but definitely take a while to break in. I've heard the Atoma plates are more consistent.

I went with a set of DMTs as my freehand stones XC, C, F, EF and the 6 micron stone. Also had the EEF but I could never get it broken in properly, so I sent it back for the 306UF stone and use that for finishing. I liked the DMTs because they can be used wet and dry with no flattening needed, but definitely take a while to break in. I've heard the Atoma plates are more consistent.

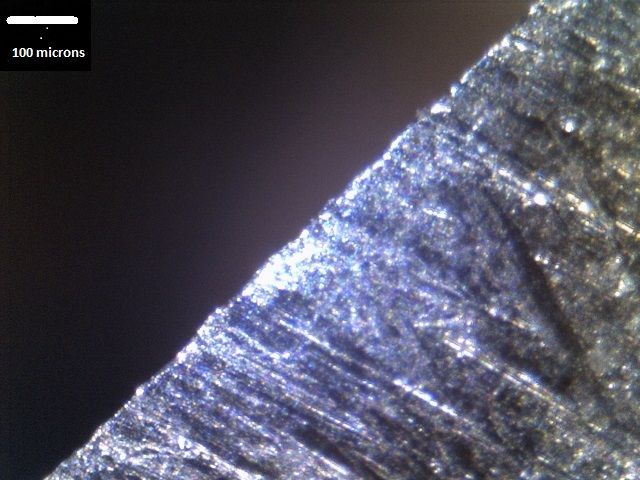

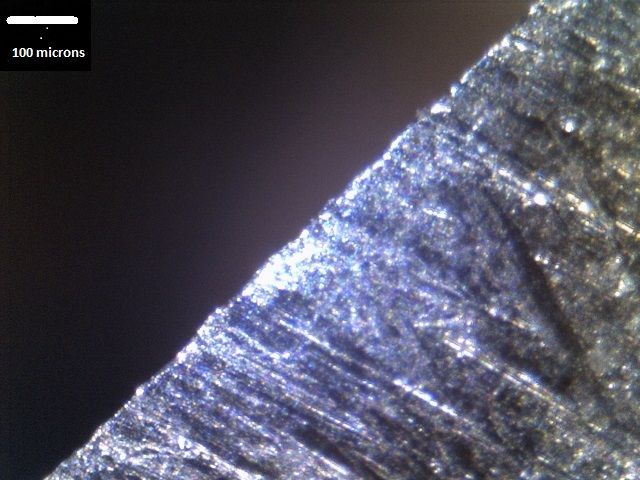

Click here to zoom: Under the Microscope

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

Travis (razorsharp) will be one of the guys to ask about that, but I'm getting very good results on Spyderco's ultra fine stone. It was a night/day difference between the DMT EEF and the UF stone, I haven't looked back.

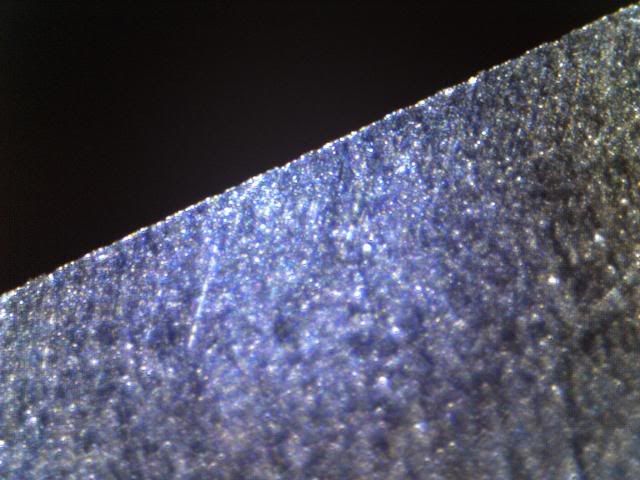

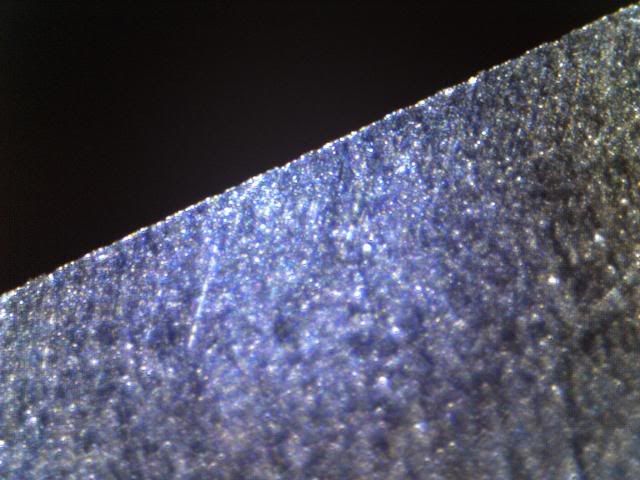

A lot of guys get into the CBN sprays and really small micron finishes but once I put the 10k Chosera edge on some o my blades I find I don't want to use them :) so I stick with a polished bevel, medium stone microbevel.

A lot of guys get into the CBN sprays and really small micron finishes but once I put the 10k Chosera edge on some o my blades I find I don't want to use them :) so I stick with a polished bevel, medium stone microbevel.

Click here to zoom: Under the Microscope

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

If you are working with very high carbide steels, especially the extreme ones and HSS, then the Sigma Power Series stones are waterstones made for that, so if you are looking at waterstones they would seem to be the obvious choice.

However, unless you are working on Japanese style knives where you have a wide bevel and you are actually bringing on the final polish on that bevel itself there is no need and no real benefit to getting a massive stone grit range.

With proper use of relief and micro-bevels you need at most three stones and even that is to handle extreme conditions in steels :

-an exceptionally coarse stone to remove lots of metal, angle changes, visible chips

-a medium stone which does the bulk of sharpening

-a finishing stone

Decent choices are :

-cheap garden store hones

People ignore these, but you can buy them locally for ~$5 and they work extremely fast because they are very low grit as in the grit rating is in the double digits. I do not recommend you apex an edge with them unless you are experienced in handling stones as you can damage an edge but with a little practice you can stop right as the edge starts to apex and then move to the medium stones.

But it is possible to do this with that stone :

A higher end version of this are the general 200 grit stones, I like the Sigma Power Select II stone in that range which doesn't cut as fast, but wears slower and is easier to control. But is also more than 10X the cost.

Medium stones :

-Bester 700 for ATS34/S30V class steels

-SPS-II 1000 for the higher carbide ones

These stones can leave a very fine edge, under 50X magnification the edge can be a straight line :

Aside from the first sharpening, or when a knife is really damaged, this is likely going to be your most used stone.

For finishing :

-Spyderco Ceramics

-DMT/Atoma Plates

are very nice for setting the final micro-bevel and are much easier to do with than waterstones. However the knife has to be properly apexed off of the medium stone, it should :

-be shaving

-slicing newsprint readily

-hint at being able to do a true-push cut

the final bevel is then set with very few passes which are very light and that just sets the edge at the exact grit you want for the cutting ability. The medium stone mainly just gets right of the rough shaping stone gouges and for general work brings it to a working apex.

The main thing to keep in mind is that tools are a far and distant second to technique. If you can't do this : https://youtu.be/mSt2mCWGFII then better stones won't help much. If you can, they make it a lot easier.

However, unless you are working on Japanese style knives where you have a wide bevel and you are actually bringing on the final polish on that bevel itself there is no need and no real benefit to getting a massive stone grit range.

With proper use of relief and micro-bevels you need at most three stones and even that is to handle extreme conditions in steels :

-an exceptionally coarse stone to remove lots of metal, angle changes, visible chips

-a medium stone which does the bulk of sharpening

-a finishing stone

Decent choices are :

-cheap garden store hones

People ignore these, but you can buy them locally for ~$5 and they work extremely fast because they are very low grit as in the grit rating is in the double digits. I do not recommend you apex an edge with them unless you are experienced in handling stones as you can damage an edge but with a little practice you can stop right as the edge starts to apex and then move to the medium stones.

But it is possible to do this with that stone :

A higher end version of this are the general 200 grit stones, I like the Sigma Power Select II stone in that range which doesn't cut as fast, but wears slower and is easier to control. But is also more than 10X the cost.

Medium stones :

-Bester 700 for ATS34/S30V class steels

-SPS-II 1000 for the higher carbide ones

These stones can leave a very fine edge, under 50X magnification the edge can be a straight line :

Aside from the first sharpening, or when a knife is really damaged, this is likely going to be your most used stone.

For finishing :

-Spyderco Ceramics

-DMT/Atoma Plates

are very nice for setting the final micro-bevel and are much easier to do with than waterstones. However the knife has to be properly apexed off of the medium stone, it should :

-be shaving

-slicing newsprint readily

-hint at being able to do a true-push cut

the final bevel is then set with very few passes which are very light and that just sets the edge at the exact grit you want for the cutting ability. The medium stone mainly just gets right of the rough shaping stone gouges and for general work brings it to a working apex.

The main thing to keep in mind is that tools are a far and distant second to technique. If you can't do this : https://youtu.be/mSt2mCWGFII then better stones won't help much. If you can, they make it a lot easier.

Wow Cliff, thank you very much for the great explanation! Very kind of you! I'll definitely check those stones out. If I don't go the water stone route, will the DMT set (C, F, XF) be suffienct to learn more on?

EDIT: Might get the Sigma Power set available at toolsfromjapan. These stones seem highly regarded. Didn't know about them until now. Thanks again Cliff.

EDIT: Might get the Sigma Power set available at toolsfromjapan. These stones seem highly regarded. Didn't know about them until now. Thanks again Cliff.

-

RanCoWeAla

- Member

- Posts: 1041

- Joined: Fri Feb 24, 2012 10:15 am

- Location: 36280

I say you need to be able to feel what you are doing first. I suggest the Spyderco Medium and Fine 2x8 stones for starting.

It's really tough to feel what you are doing and I believe you need to know what you are doing before jumping to the diamond stones. I feel like I'm partially blind, and just going by what I know from other stones when I'm using the DMT stones. I'm not too sure how the shapton glass feels.

It's really tough to feel what you are doing and I believe you need to know what you are doing before jumping to the diamond stones. I feel like I'm partially blind, and just going by what I know from other stones when I'm using the DMT stones. I'm not too sure how the shapton glass feels.

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Yes, a few things :btron wrote:...will the DMT set (C, F, XF) be suffienct to learn more on?

-go very light, use that small an amount of force that it seems like not enough and then cut that in half

I can't over state this enough, they require very little force to cut. If you want to see just how light then get a very nice mirror polished blade and drag it very lightly across a diamond stone and watch how it is cut into no matter how light you try to make the contact. Steel is extremely soft compared to diamonds, the difference is much higher than the difference in hardness between steel and a pillow.

For example on CBN rods which are very similar : https://youtu.be/xRQQgwRMDfU

-use some kind of lubricant on the stone

I use water, but if you are not careful this can cause corrosion, just rinse the stones very well after use and pat them dry. There are special solutions available, but they are expensive and I have not seen any issue with water. The reason you need water is that you don't want to breath in the dust and it isn't good for anything else either and it will allow the knife to glide over any irregular spots.

-be aware that diamond stones are tru-flat and don't slurry

Most stones will wear, this creates a hollow and they build up a slurry - both of these cause an angle increase and an averaging/smearing out of the final edge angle. This means you can be sloppy in angle to the stone and still get an apex. This doesn't happen with diamonds, if you hone at 16 dps and then at 17 dps you just get two bevels. On waterstones this just smears out into one bevel which is around 16-17 dps and the smearing out gets larger with more slurry and wear on the stones, it can easily be 3-5 dps.

I was always under the impression that pull through sharpeners really mess up your edge.RanCoWeAla wrote:You guys must have an unlimited supply of cash. I use a Case xx Arkansas oil stone about

1" x 5" and a six dollar Smith's pull through with ceramic sticks on my keychain

I don't have any good experience to back that up, though. I normally think if I have a ding in my edge, what the pull through sharpener would do to it.

-Brian

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

A distinguished lurker.

Waiting on a Squeak and Pingo with a Split Spring!

My favourite stone is an 11" benchstone, just having something that big seems to make the task a lot easier.

You can get them at Lee Valley (http://www.leevalley.com/en/Wood/page.a ... at=1,43072).

You can get them at Lee Valley (http://www.leevalley.com/en/Wood/page.a ... at=1,43072).

I know the ones with the tungsten carbide teeth will screw it up in.a hurry, but haven't seen any micrographs of what the ceramic rods on a pull-through sharpener will do.Donut wrote:I was always under the impression that pull through sharpeners really mess up your edge.

I don't have any good experience to back that up, though. I normally think if I have a ding in my edge, what the pull through sharpener would do to it.

Click here to zoom: Under the Microscope

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

Manix2, Elmax MT13, M4 Manix2, ZDP Caly Jr, SB Caly3.5, Cruwear MT12, XHP MT16, South Fork, SB Caly3, 20CP Para2, Military Left Hand, Perrin PPT, Squeak, Manix 83mm, Swick3, Lil' Temperance, VG10 Jester, Dfly2 Salt, Tasman Salt

Chris

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

There are many varieties, some are very mild abrasives, very fine ceramic rods, some are sharp edged pieces of tungsten carbide. The problem comes when people press really hard to try to speed up sharpening, now to be fair they often see this recommended. If you do this the edge will get distorted heavily. But they are made for people who consider ultimate sharpness the ability to slice a piece of paper and they will get that from those sharpeners.Donut wrote:I was always under the impression that pull through sharpeners really mess up your edge.

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Which stones did you order?btron wrote:Can't wait to get my water stones! Ordered some last night. Should be in my mailbox Friday :)

I use Shapton glass 320, 1k, 4k, 8k bench stones. I also use the Spyderco fine and UF for quick touch ups. I have DMT XC-EF also. I really like these stones but seldom use them now. Depending on which grits you got ordered, I'd suggest a DMT X-coarse as an economical coarse grit. With it you also have a good flattening stone. After learning to use DMT stones they are great. About breaking them in? If you get a coarse on you will break it in very quickly by using it to flatten your water stones. JUST USE LIGHT PRESSURE when using diamond stones. They WILL be cutting even when you can't feel it. Also using too much pressure can ruin the stones. Use light pressure when flattening water stones also. My choice is my Shapton glass along with the Spyderco fine and UF. My choices came from some (but not a LOT) of trying different stones. IMO, I like the Spyderco stones more than DMT for grits in that range. Personal choice. One thing I believe is if you get anything recommended so far they are good stones and will work well. I don't think any stones are EVERYONE'S personal favorites.

Enjoy. :)

Jack

I went with the Shapton glass 500, 1k, 4k, 8k. I also got the DMT D8C. I was going to go with Cliff's recommendation of the Sigma Power Select II, but ended up going with Shapton at the last minute. I read way too many good reviews, even with the powdered steels and the like. And hey, if they don't fit my needs, I guess I can always sell and go with the Sigma at a later date. But numerous reviews say they are no problem with what steel I'm going to be sharpening.jackknifeh wrote:Which stones did you order?

I use Shapton glass 320, 1k, 4k, 8k bench stones. I also use the Spyderco fine and UF for quick touch ups. I have DMT XC-EF also. I really like these stones but seldom use them now. Depending on which grits you got ordered, I'd suggest a DMT X-coarse as an economical coarse grit. With it you also have a good flattening stone. After learning to use DMT stones they are great. About breaking them in? If you get a coarse on you will break it in very quickly by using it to flatten your water stones. JUST USE LIGHT PRESSURE when using diamond stones. They WILL be cutting even when you can't feel it. Also using too much pressure can ruin the stones. Use light pressure when flattening water stones also. My choice is my Shapton glass along with the Spyderco fine and UF. My choices came from some (but not a LOT) of trying different stones. IMO, I like the Spyderco stones more than DMT for grits in that range. Personal choice. One thing I believe is if you get anything recommended so far they are good stones and will work well. I don't think any stones are EVERYONE'S personal favorites.

Enjoy. :)

Jack

Thanks for the tips Jack!