I meant to discuss this in the video on the CBN, in some detail, (if you are not interested in the why just skip to the bottom -- part ):Bill1170 wrote:We know that diamond stones break in with use, assuming a less aggressive grit than when new. CBN may do the same.

All abrasives, in fact all edges, or anything that wears tends to wear (or blunt, deform, etc.) at a rate which is inversely proportional to the extent of wear, that means that the more wear it has taken, the more the rate of wear decreases. It is easy to understand this if you take a sharp edge piece of wood and consider the edge thickness which is likely so small you have a hard time seeing it, some small fraction of a mm for a sharp square corner. Now take a sheet of sandpaper and rub it along the edge and you will find the edge makes a dramatic increase in thickness. Rub the sandpaper again and you will see the thickness increase but not as dramatic. Of course as the edge gets thicker you have to remove more material to make it thicken further and thus while initially one pass can easily double (or triple) the thickness, one pass at the 50'th point might make such a small percentage change that you can not even see it.

If you do the math this means you end up with a general solution which looks like : W(x)=axb+c. Here :

W(x) is the wear at a number of passes (x)

a,b,c are physical constants (depend on the materials, manner of work, etc.)

Now the grinding ability (G) is just the inverse of this and that equation is :

G(x)=G_0/(1+axb)Here I have replaced c with G_0 for the initial boundary condition that at x=0 the grinding rate is just the initial (or as-boxed) grinding ability G_0.

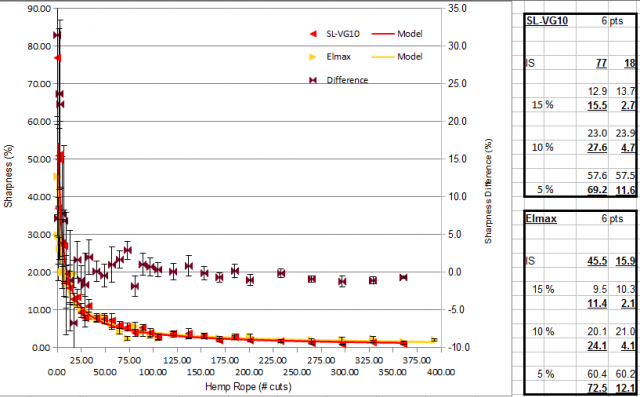

Now if you plot this curve in general you get something which looks like :

This curve is comparing two blades for edge retention, but for the purposes here just look at the red/yellow lines/points and see how they decrease very rapidly initially but then tail off, that is what that curve looks like in general and it holds well for all general wear-type relations no matter the material.

--

In short, all abrasives will wear rapidly at first and then settle into a long plateau region where their rate of wear is so slow they basically stay there effectively forever under normal use. I have a diamond stone which has been used for ~20 years and is the same stone that I do all the 600 grit comparisons with and does a lot of my finish sharpening for general utility. I take micrographs of the edges it produces ever few years and they are not significantly difference under 50X magnification.

The reason why people state this for diamonds and not for say water stones is that for waterstones as the grit wears they also break away from the bond and new ones are released, and they also fracture and produce new cutting edges. This allows the surface to maintain a consistent cutting pattern because the worn grits are simply replaced. However if you have ever used a grinding wheel with an extremely dense/tight bond you can see it smooth out and have to be resurfaced as the grits are wearing down and the bond holds them so tight that new ones are not released.

Now what I would recommend is different than what a lot of people say about using plated abrasives which is use them first on some cheap knives. I would not recommend that because often it makes people intentionally try to "break them in" by pushing too hard/fast and this will tear out the abrasive or break it apart. What I would recommend is :

-use water

This has many benefits :

-acts as a lubricant which will allow the edge to skip over any really rough patches

-catches the dust (keeping it out of the air and your lungs)

and second :

-go light

I mean light here as in the least force you can apply. These abrasives (diamond/cbn) are extremely hard and very sharp, to them steel is very soft, it is like comparing steel to butter. They will cut it with extremely low force, especially when new when all of these edges are very sharp. If you want to cut faster just use a more coarse grit, but always keep the force very low. As the abrasive wears then you can slowly increase force, the goal is to keep the feel the same.

Essentially this is called finding the sweet spot in grinding, the amount of force you have to apply to get the grits to cut at a depth which gets the grits to cut deep enough so there isn't any skipping, but not so deep they get torn out, they just wear slow. With diamond and cbn, I have found that initially, this force (especially on narrow stones) is really light.