sal wrote:

Let me know if you want a set to test?

Sure.

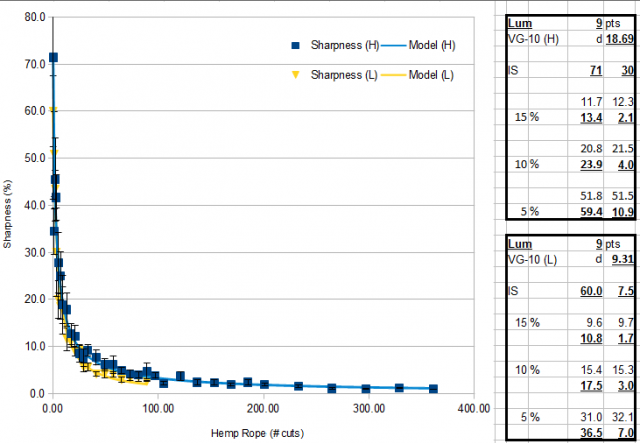

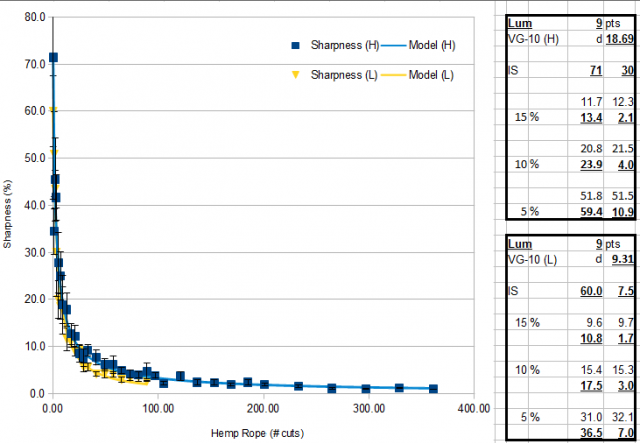

This is the result of three runs, at this point the predictive power is about 15%. I was hoping it would be a little better, but based on the math that is about what I would expect there are just so much variances in hand cutting (speed, force, angle, material, environmental conditions, initial sharpness, steel consistency) .

I can probably get it under 10% but in order to do that I would have to increase the run count way up to 10, I might do that at some point just to check the math and verify that the variations are random (the systematic ones will not average out), but it likely won't be for awhile.

The problem is though that at +/- 15% this means you can only see coarse differences because this means that in order to see a difference in a steel it has to be bigger than twice this variation (as they add when you difference). This means that VG-10, ATS-34, AUS-8, S30V, etc. all measure the same.

I will add a couple of knives to show the extreme points which should be picked up, a ZDP-189 Spyderco and I will see if I can't get one of the ones in the 420 or similar steel as well to show where the low point falls.