It depends on what you are cutting and how. If you are :jackknifeh wrote:...I'd think a toothy edge would have less edge retention because I'd think the very tiny teeth might snap off

-push cutting

-cutting hard materials

then a higher polish will provide higher edge retention, however if you are :

-slicing

-cutting soft materials

then both initial cutting performance and edge retention can be increased with a coarse finish.

If you want to see this on a macroscopic scale then take two saws :

-one with a very coarse TPI

-one with a very fine TPI

and try cutting some very soft and very hard wood.

I would not think so.Blerv wrote: In this case besides corrosion resistance and purchase price would vg10 have any advantage?

If that is what you take from what I wrote then I don't know what to say aside from the fact that nothing I wrote implies that.arty wrote:From your answer, it sounds like you don't gain much from Superblue, unless you want to cut fish for sushi and you do this for hous on end.

I can't give you the answer you want. There are lots of people who will readily give you very simple and very exact answers to your question. Now they will be wrong, but they won't be complicated.

The reality is that the answer to your question isn't so trivial that you can just pick a number, if it was I would have just given it. Anyone who gives you such a simple answer either :

a) doesn't know what they are talking about

b) is trying to sell you something

Here is a question :

What has better edge retention 1075 at 52/53 HRC or VG-10 from Spyderco at 59/60 HRC?

Does it change if I add more detail :

What has better edge retention slicing cardboard with a 600 DMT finish - 1075 at 52/53 HRC or VG-10 from Spyderco at 59/60 HRC.

How about even more detail :

What has better edge retention slicing cardboard with a 600 DMT finish - 1075 at 52/53 HRC or VG-10 from Spyderco at 59/60 HRC with a 14-16 dps micro-bevel and a 7-9 dps primary bevel.

Most people will immediately jump to VG-10 to all questions, if you are aware of edge stability then you should hesitate when they see 7-9 dps behind the micro-bevel.

Before you reach your final conclusion :

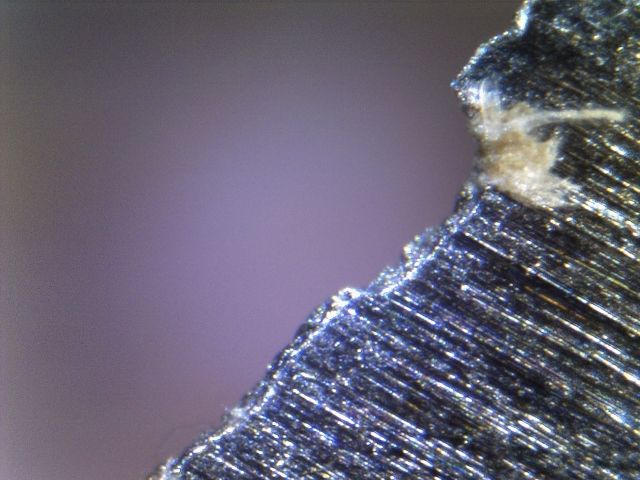

This is a 50X magnification shot of a Lum, the damage is too extensive to get in the FoV at 50X magnification as it is visible by eye.

The answer to the above is in this case it was the 1075 blade at 52/53 HRC because the VG-10 blade was fracturing and losing large pieces out of the edge and the 1075 was just taking slow wear.

However when the VG-10 doesn't fracture then it has a about a 50% improvement in edge retention, but if the cardboard is hard and stiff enough that it causes the force to rise above a critical level then the VG-10 starts fracturing.

This kind of extreme fracturing can't happen with 1075 at 52/53 HRC (and much higher) because it is much more stable at thin cross sections than VG-10. But again :

-if you are cutting soft materials

-you are cutting slow

-not exerting much force

then you won't fracture VG-10 and thus it will pull ahead as it reduces to wear resistance mainly.

The answer to the question is :

-if the cardboard is hard/stiff enough to cause fracture, then 1075, otherwise VG-10

Now at some point if you keep increasing the primary bevel angle the VG-10 will stop fracturing - however the angle that is necessary to stabilize it will depend on :

-the stiffness of the cardboard

-the thickness

-the speed of the cut

-control/efficiency in the cut

and so again you can't simply say VG-10 will stabilize at 15 dps (or whatever) anyone who says that is just making things up. The question is then do you want an answer which is simple (and wrong) or do you want the truth?