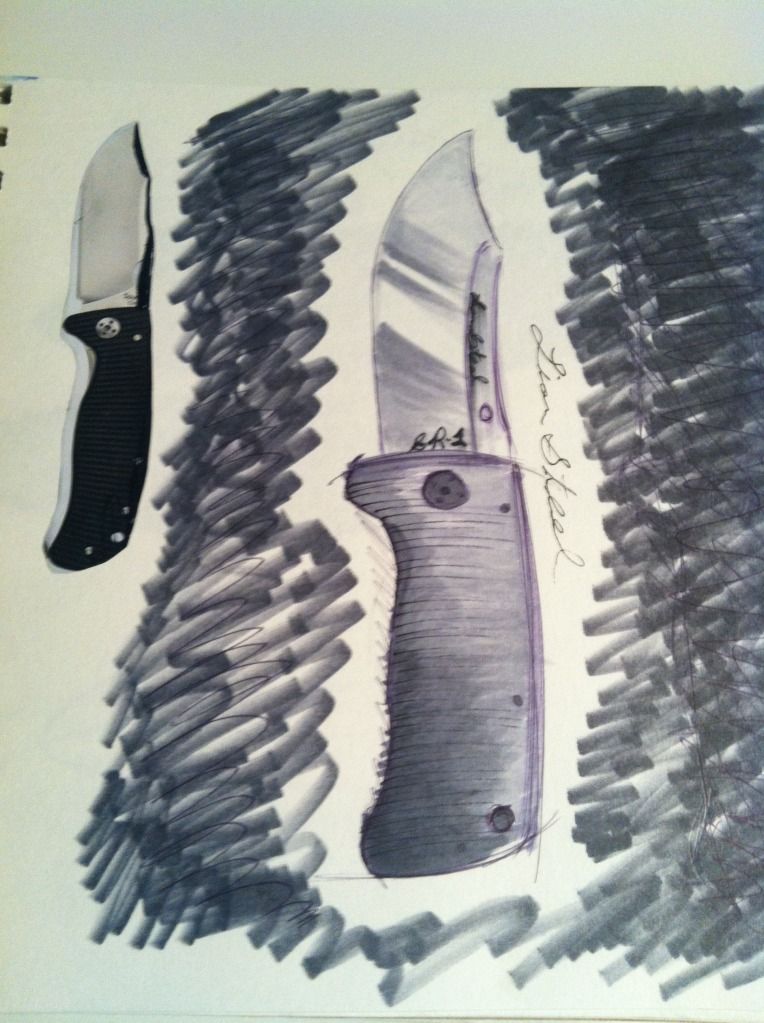

(there is a small pre-production pic of the lion spy that I used for reference)

Well recently, I won a lightly used Lionspy that happened to be a stores display model. I got it for $240, so Initially I was really excited, since this was a model, and steel, that I have been waiting on. When it got here, I was not as excited. It was ground in a way where there was NO tip, the blade was way off center, and there were (and are) tooling marks on the rotoblock and scratched on the Ti. At first I tried to restore the tip with a 220 norton bench stone, eventually resorting to droping the point slightly by grindint the top of the tip to meet the bevel. I wasnt happy with this at all, and was contemplating selling it. Then I found that pic. And well... about an hour later, I am now very happy with it!, The blade is still a little off center, but I can live with that now that I have made it more my own...

(Ti side was stone washed and then immediately heat anodized)

Inside the rotoblock in case you were wondering...

Over all, I could not be happier! I finally have my folding bowie! I find the clip point to be FAR more useful than the shape from the factory. Felt very stubby and cumbesome when using the tip. Not any more!