I understand the words but not the ideas. :DAnkerson wrote:I think they are looking for something that just doesn't exist currently and definitely not in production knives.

The steels just ain't there nor is the hardness and the tempering process.

That is if they are cutting more than a bag of chips or opening mail.

That is unless they are farming out to someone with a 10 Bar + Furnace and getting MAX hardness, that's getting into Aerospace quenching speeds...

Fine Edge Retention

- chuck_roxas45

- Member

- Posts: 8776

- Joined: Wed Mar 03, 2010 5:43 pm

- Location: Small City, Philippines

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

Basically that is production knives have to be made to suit a variety of users and uses so they have to find a balance or should I say compromise that will fit the large client base.chuck_roxas45 wrote:I understand the words but not the ideas. :D

Same goes for the reason why we don't see production knives that are ground very thin, instead they are usually in the .025" + range behind the edge.

Spyderco is the best at this IMO.

I try to keep very fine edges on my knives, but am dissapointed often after tough usage, and see edge curl and chipping. My experience has been mostly with VG-10, S30V, and CPM 154 ... that's why I've been asking about the newer powder steels ... don't these newer steels help with that problem (fine edges included) in general?Ankerson wrote: I am guess those who are worried about it really aren't cutting much with their knives or using them that much because if they cut anything that is abrasive that fine edge will be gone very fast. Just keeping it real here.

ELMAX and XHP are going to be at the top of that list I think as will CPM 154.JB3 wrote:I try to keep very fine edges on my knives, but am dissapointed often after tough usage, and see edge curl and chipping. My experience has been mostly with VG-10, S30V, and CPM 154 ... that's why I've been asking about the newer powder steels ... don't these newer steels help with that problem (fine edges included) in general?

But then it really will depend on hardness, edge finish and edge geometry.

Yeah I know none are readily avaible in a broad since right now.

There are other steels also, but at this point they aren't avaible in production blades.

I am really liking XHP a lot for harder cutting tasks though.

I used it for a month straight at work (Military) and it performed extremely well, I can say better than ANY steel in ANY production blade I have ever used. Yeah I saw normal edge wear etc as I do tend to do some very hard cutting, but overall I was very impressed. That's for what I normally cut and how I use my knives at work.

It reminds me of ZDP, but better and tougher.

- chuck_roxas45

- Member

- Posts: 8776

- Joined: Wed Mar 03, 2010 5:43 pm

- Location: Small City, Philippines

Thanks for taking the time to explain.Ankerson wrote:Basically that is production knives have to be made to suit a variety of users and uses so they have to find a balance or should I say compromise that will fit the large client base.

Same goes for the reason why we don't see production knives that are ground very thin, instead they are usually in the .025" + range behind the edge.

Spyderco is the best at this IMO.

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

Good to hear about XHP. Be careful, though, you're starting to sound like a certain someoneAnkerson wrote: I am really liking XHP a lot for harder cutting tasks though.

I used it for a month straight at work (Military) and it performed extremely well, I can say better than ANY steel in ANY production blade I have ever used. Yeah I saw normal edge wear etc as I do tend to do some very hard cutting, but overall I was very impressed. That's for what I normally cut and how I use my knives at work.

It reminds me of ZDP, but better and tougher.

Tom

__________________________________

[url]http://spydercovt.com[/URL]

__________________________________

[url]http://spydercovt.com[/URL]

Junior avatar courtesy of dialexSequimite wrote:I use knives. I collect experiences.

I'm an admirer of Spyderco's designs. Using them is like immersing yourself in music or studying a painting in a museum. I buy some "fine" art but my preference is for usable art.

- phillipsted

- Member

- Posts: 3674

- Joined: Tue Oct 05, 2010 11:30 am

- Location: North Virginia

My experience with ZDP-189 has been phenomenal - and I agree that the edge is a bit more well suited to fine cutting tasks than other steels. But if you are zipping open envelopes, opening packages, cutting paper, and other office tasks - ZDP will maintain an extreme level of sharpness for weeks under heavy normal usage.

TedP

TedP

Worry less - Breathe more...

Spydie Fanatic #185

Spydie Fanatic #185

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

No, they are designed to be high wear, you are looking for high edge stability. It is completely different. Edge stability decreases as carbide volume increases.JB3 wrote:I try to keep very fine edges on my knives, but am dissapointed often after tough usage, and see edge curl and chipping. My experience has been mostly with VG-10, S30V, and CPM 154 ... that's why I've been asking about the newer powder steels ... don't these newer steels help with that problem (fine edges included) in general?

I think something in the middle of the road is ideal.Cliff Stamp wrote:No, they are designed to be high wear, you are looking for high edge stability. It is completely different. Edge stability decreases as carbide volume increases.

We can have all the edge stability in the world, but if the blade gets butter knife dull after a few cuts it's not much good.

Also on the other end, if the edge falls apart chipping out, rolling, flattening ect that's not much good either.

That's why I tend to lean towards the High Carbon, high Carbide steels at high hardness. The Carbides give us the edge retention and the high hardness helps a lot with edge stability. That's with a proper HT and tempering process though.

I appreciate your insights and would only add that your post illustrates a factor I try to point out frequently. That is: "What you intend to do with the knife is important."Ankerson wrote:I think something in the middle of the road is ideal.

We can have all the edge stability in the world, but if the blade gets butter knife dull after a few cuts it's not much good.

Also on the other end, if the edge falls apart chipping out, rolling, flattening ect that's not much good either.

That's why I tend to lean towards the High Carbon, high Carbide steels at high hardness. The Carbides give us the edge retention and the high hardness helps a lot with edge stability. That's with a proper HT and tempering process though.

Your work uses might render an edge dull in a few cuts, another man might have the same edge last several days in the woods.

Couple this concept with what I believe to be the subject of this thread, and it becomes apparent that some people have uses for knives that show great preference for fine edge retention. And that is why they are not wrong (IMO) for tending to a different ideal blade chemistry than you may hold.

I totally agree that industry is wise to shoot for middle of the road...that is where most people probably travel. Some of us travel alternate paths, and perhaps none are wrong, but many are different

Thanks,

Ken (my real name)

...learning something new all the time.

Ken (my real name)

...learning something new all the time.

There is really no bad, just different. :)unit wrote:I appreciate your insights and would only add that your post illustrates a factor I try to point out frequently. That is: "What you intend to do with the knife is important."

Your work uses might render an edge dull in a few cuts, another man might have the same edge last several days in the woods.

Couple this concept with what I believe to be the subject of this thread, and it becomes apparent that some people have uses for knives that show great preference for fine edge retention. And that is why they are not wrong (IMO) for tending to a different ideal blade chemistry than you may hold.

I totally agree that industry is wise to shoot for middle of the road...that is where most people probably travel. Some of us travel alternate paths, and perhaps none are wrong, but many are different

People do have different purposes for their knives.

Sometimes I run into things that will totally waste the edge and all I can do is laugh about it and fix it when I get home.

Waiting for Spyderco to come out with folders in ELMAX and M390 though.

Although the ulimate would be K294 or K390 if that ever happens, K294 is very fine grained and will take one heck of a fine edge and hold it for a very long time. :D

Thanks everyone for making this an excellent and informative discussion.

I'm really not against working edge retention, I just don't want to sacrifice fine edge retention and/or ease of sharpening to get it.

IME, CTS-XHP offers a great balance of fine edge retention, working edge retention, and ease of sharpening. I'm looking forward to using :spyder: s in Elmax, M390, and CTS-204P, as they have the potential to take this balance even further.

It really is a great time to be a knife/steel knut :)

I'm really not against working edge retention, I just don't want to sacrifice fine edge retention and/or ease of sharpening to get it.

IME, CTS-XHP offers a great balance of fine edge retention, working edge retention, and ease of sharpening. I'm looking forward to using :spyder: s in Elmax, M390, and CTS-204P, as they have the potential to take this balance even further.

It really is a great time to be a knife/steel knut :)

Tom

__________________________________

[url]http://spydercovt.com[/URL]

__________________________________

[url]http://spydercovt.com[/URL]

Junior avatar courtesy of dialexSequimite wrote:I use knives. I collect experiences.

I'm an admirer of Spyderco's designs. Using them is like immersing yourself in music or studying a painting in a museum. I buy some "fine" art but my preference is for usable art.

Now I know why I spend so much time here. A lot to learn and I get to play with my toys while learning.Cliff Stamp wrote:You are going to get a large variance in feedback here until you narrow down two things; what is the edge angle you are using and what polish do you use to finish the knives?

If your edge angle is high (15+ degrees) and/or your edge finish is coarse, then steels will stay sharp the higher the carbide volume and the harder the edge and the lower the amount of retained austensite.

If however your edge angles are low, your edge is highly polished then steels will stay sharp the lower the carbide volume, the harder the steel and the lower the amount of retained austensite.

Note the list Mastiff posted is of the second type (low carbide), the list Jankerson posted is of the first type (high carbide).

Note regardless of the type, all steels will blunt very quickly fast if they are not properly deburred. This is one of the reasons why some steels get a reputation for fine edge holding as they simply don't burr much in sharpening.

For example, ATS-34 at 58 HRC will burr much more readily than 8Cr13MoV at 61 HRC. Thus even if you use high edge angles where AST-34 should be able to hold a high sharpness, if you don't deburr it 8Cr13MoV will still be superior - this sharpening skill will make a large difference.

Certainly some things that I need to think more about when I sharpen that I've never even considered. Great post. :spyder: :spyder: :spyder:

Ankerson, Cliff Stamp

When talking about carbides do you refer to the following explanation thereof:

Carbides - Simple explanation: Hard particles formed in steel when carbon forms with iron or transition metals.

In depth: Carbides control greatly the level of wear resistance and toughness in a steel. Because carbides are extremely hard, a great volume of them will make a steel very brittle, especially if the carbides are large and unevenly distributed. Steels vary from nearly 0% all the way to 30% carbide volume. (Auth. Larrin Thomas)

Taken from zknives

My reference to carbides are a bit different and just curios.

When talking about carbides do you refer to the following explanation thereof:

Carbides - Simple explanation: Hard particles formed in steel when carbon forms with iron or transition metals.

In depth: Carbides control greatly the level of wear resistance and toughness in a steel. Because carbides are extremely hard, a great volume of them will make a steel very brittle, especially if the carbides are large and unevenly distributed. Steels vary from nearly 0% all the way to 30% carbide volume. (Auth. Larrin Thomas)

Taken from zknives

My reference to carbides are a bit different and just curios.

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

Is there a benchmark for a "very fine edge". I'm sharpening now with thought to the material and probable use. No blade material is perfect. To me a percieved very fine edge is dependent on the subjective expectations of the user.

Charlie

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

" Everything should be made as simple as possible, but not one bit simpler."

[CENTER]"Integrity is being good even if no one is watching"[/CENTER]

- chuck_roxas45

- Member

- Posts: 8776

- Joined: Wed Mar 03, 2010 5:43 pm

- Location: Small City, Philippines

For my fine edges, I am content with one that whittles hair both ways(with and against the grain).dbcad wrote:Is there a benchmark for a "very fine edge". I'm sharpening now with thought to the material and probable use. No blade material is perfect. To me a percieved very fine edge is dependent on the subjective expectations of the user.

http://uproxx.files.wordpress.com/2014/ ... ot-gif.gif" target="_blank

- matrixone976

- Member

- Posts: 17

- Joined: Mon Nov 14, 2011 6:26 pm

hey its ewerstruly from YT!!!unit wrote:No doubt in my mind CPM-M4 will put up with a huge amount of abuse and still shave arm hair, etc.

This is a video I did a while back of a practice session I did with a chopper made of CPM-M4. You will have to take my word on the matter that I did a LOT more than what is shown in the video prior to the edge demonstration...it would also shave leg hair cleanly in a single pass at this point.

Also worth noting, I reprofiled this edge. It is a bit thinner at 1mm behind the edge than many EDC blades you might carry.

<iframe width="420" height="315" src="http://www.youtube.com/embed/CR0jbSQghPk" frameborder="0" allowfullscreen></iframe>

It is worth noting that ZDP will also retain a keen edge VERY well, but it will not put up with this sort of percussive cutting. If you are using a folder sensibly, ZDP will amaze your friends

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Edge stability is a measure of edge retention. It is just restricted to edge retention at very high levels of sharpness at very low angles. If a steel had "all the edge stability in the world" it would never get dull as again edge stability is a measure of how much work it takes to dull it.Ankerson wrote:

We can have all the edge stability in the world, but if the blade gets butter knife dull after a few cuts it's not much good.

Blunting is nonlinear, edge stability is simply the early response. To be specific :

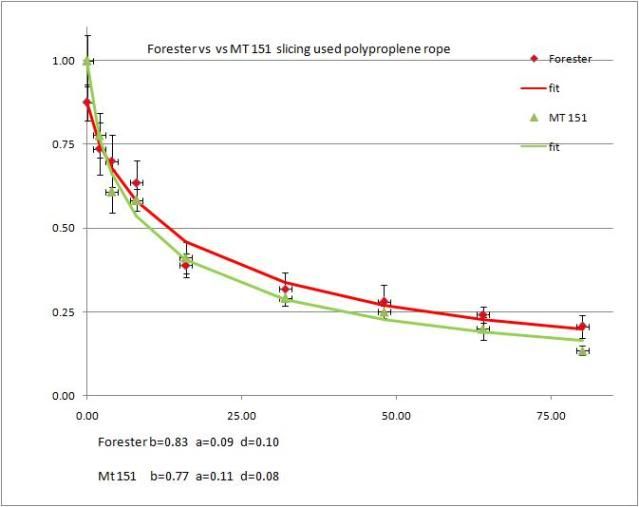

This is a blunting curve comparing N690 (Forester) to 440A (Mtech) on used polypropylene rope. Note the 440A is ahead early, they equalize until about 50%, a they pass 25% of optimal sharpness the advantage starts to be noticeable in favor of N690 and this is due to the blunting starting to be dominated by carbide volume entirely. By the end you have a point similar to what is reported in the CATRA tests. Note if you kept cutting with the knives getting duller and duller the N690 would keep pulling ahead further as again the response is nonlinear.

It is simply a matter of preference. Someone who uses knives when they have a very low sharpness, < 25% of optimal will appreciate the long term edge retention of N690, someone who uses knives really dull, < 5% of optimal will think N690 is fantastic as the advantage it would have then would be very large indeed. However someone who keeps their knives very sharp will see no advantage to it at all, in fact it is worse, and would pick the other steel because it is sharpens much faster, tougher, easier to grind, cheaper etc. .

Note the small increase in edge stability shown here for 440A would obviously be increased with a proper hardening to 60/61 HRC, which is about the maximum 440A will reach with a high austenization, oil + cold.

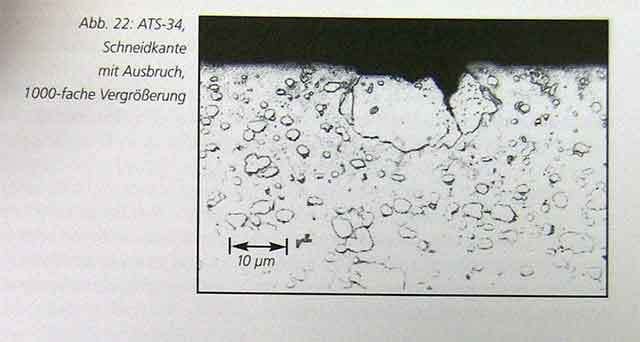

More or less yes, here is a high carbide steel which has large aggregate carbides (ATS-34) :Zenith wrote:

When talking about carbides do you refer to the following explanation thereof:

Carbides - Simple explanation: Hard particles formed in steel when carbon forms with iron or transition metals.

This is what happens to such steels which you sharpen them at low angles :

The carbides just tear out and keep tearing out until the edge thickens (dulls) to the point it can contain them.

Here is a low carbide steel which has very well dispersed, very fine carbides (AEB-L) :

Cliff Stamp

Thank you for the explanation. Two last questions. Does the CPM or similar process help with carbide distribution?

Reason I ask is I sharpen most of my knives at low angles. Including CPM-M4 and RWL-34. Use it on the farm and at work cutting hard rubber/plastic pipes sometimes and it has staid sharp for a long period of time.

I prefer finishing my edges on green compound to mirror finish and maintain it there because if I am at a rig I can go to a courser micro edge (600grit) with ease. It is harder to go to a finer grit, but one can always go to a courser grit if required with ease in my experience.

Finally. How does one know what steels are high carbide or not? Does one take the entire chemical/element composition into account? This is what seems logical to me.

Thank you for the explanation. Two last questions. Does the CPM or similar process help with carbide distribution?

Reason I ask is I sharpen most of my knives at low angles. Including CPM-M4 and RWL-34. Use it on the farm and at work cutting hard rubber/plastic pipes sometimes and it has staid sharp for a long period of time.

I prefer finishing my edges on green compound to mirror finish and maintain it there because if I am at a rig I can go to a courser micro edge (600grit) with ease. It is harder to go to a finer grit, but one can always go to a courser grit if required with ease in my experience.

Finally. How does one know what steels are high carbide or not? Does one take the entire chemical/element composition into account? This is what seems logical to me.

"If you wish to live and thrive, let the spider run alive"

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

"the perfect knife is the one in your hand, you should just learn how to use it."

If you don't have anything good to say, then don't say anything at all

My Youtube knife use videos and more: http://www.youtube.com/user/mwvanwyk/videos

Knife makers directory: http://www.knifemakersdirectory.com/

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Yes, the carbides get smaller and more well distributed but the raw amount of them is still the same. A lower carbide non-CPM steel will thus still have a higher edge stability.Zenith wrote: Thank you for the explanation. Two last questions. Does the CPM or similar process help with carbide distribution?

One of the problems in this discussion is that certain terms like "sharp" are not really consistently defined. For example do you mean sharp as in your knife can still slice a piece of newsprint, or sharp as in it can slice a piece of photocopy paper, or sharp as in it could slice a piece of 3/8" hemp rope if you yanked hard (30-40 lbs) through a loop in it? Basically, the lower sharpness you are comfortable working with (and the higher the angle) the more you will be pleased with the performance of the higher carbide steels.Reason I ask is I sharpen most of my knives at low angles. Including CPM-M4 and RWL-34. Use it on the farm and at work cutting hard rubber/plastic pipes sometimes and it has staid sharp for a long period of time.

Essentially, most manufacturers will state the carbide volume as well, and you can see it on the micro-graphs and you can calculate it from the appropriate equations. Vanadium and Tungsten are the primary carbide formers, Chromum and Molybdenum are secondary as a lot of that goes into solution when austenized to give corrosion resistance and the strong secondary hardening of those steels.Finally. How does one know what steels are high carbide or not? Does one take the entire chemical/element composition into account? This is what seems logical to me.