Laminated ZDP?

Laminated ZDP?

How does the laminated ZDP-189 on the Caly 3 CF work?

Is it a "sandwich" method, where there is ZDP on the outsides and 420 on the inside? Or vice-versa? Or is the entire belly up to that visible line ZDP-189 steel?

Thanks.

Is it a "sandwich" method, where there is ZDP on the outsides and 420 on the inside? Or vice-versa? Or is the entire belly up to that visible line ZDP-189 steel?

Thanks.

- dalefuller

- Member

- Posts: 469

- Joined: Sat Feb 26, 2005 1:37 pm

- Location: Atlanta

And yes... the lower part of the blade from the edge up to the lamination line is ZDP189.LowTEC wrote:ZDP is the inside core, and it's one of the best if not the best SS you can find right now :cool:

Regards,

Dale

"If there are no dogs in Heaven, then when I die I want to go where they went."

~ Will Rogers, 1879-1935

Dale

"If there are no dogs in Heaven, then when I die I want to go where they went."

~ Will Rogers, 1879-1935

- dalefuller

- Member

- Posts: 469

- Joined: Sat Feb 26, 2005 1:37 pm

- Location: Atlanta

Let's talk about sharpening. When you sharpen a knife, you don't run the entire side of the knife along the stones or rods. Instead, you focus on just the bevel, the angled part of the bottom of the blade that runs from the edge back up to the side of the blade. That's the only area on most knives that will contact the stone or rods.

On a ZDP189 Caly 3, that part is all ZDP189. The sharpener never comes into contact with the 420 steel above the ZDP189.

On a ZDP189 Caly 3, that part is all ZDP189. The sharpener never comes into contact with the 420 steel above the ZDP189.

Regards,

Dale

"If there are no dogs in Heaven, then when I die I want to go where they went."

~ Will Rogers, 1879-1935

Dale

"If there are no dogs in Heaven, then when I die I want to go where they went."

~ Will Rogers, 1879-1935

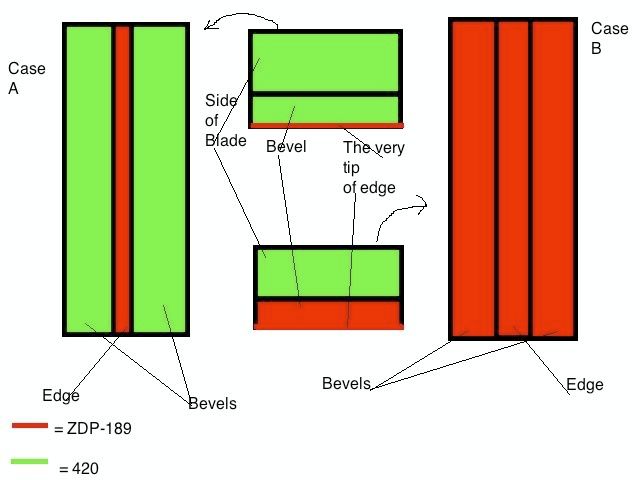

Ok, that was my original question, and everyone else replied that it is "sandwiched."dalefuller wrote:On a ZDP189 Caly 3, that part is all ZDP189. The sharpener never comes into contact with the 420 steel above the ZDP189.

So looking at that knife with the edge pointing downward, below that "line" on the blade, everything is ZDP, right? If I were to touch the blade on the side under that line, I would be touching ZDP-189, and if I were to touch the edge, I would also be touching ZDP-189, correct?

Just for clarification:

Is it case A (sandwhiched) or case B (everything below the line is ZDP)?

- araneae

- Member

- Posts: 5491

- Joined: Wed Aug 09, 2006 10:10 pm

- Location: A lil more south of the Erie shore, Ohio

Not quite sure about your diagrams, but I don't think you have it right yet. The Zdp is in fact sandwiched between 420, however the way the knife is ground means that below the lamination line you only see ZDP. The cutting edge is pure ZDP. Higher up to the spine you have a sandwich of 420.THG wrote: Is it case A (sandwhiched) or case B (everything below the line is ZDP)?

So I think the answer to both of the above questions is yes. Does that make sense?

So many knives, so few pockets... :)

-Nick

Last in: N5 Magnacut

The "Spirit" of the design does not come through unless used. -Sal

-Nick

Last in: N5 Magnacut

The "Spirit" of the design does not come through unless used. -Sal

what would be the advantage of that? what would be the advantage of sandwiching the two steels? samurai swords were constructed differently,( imagine a V shape .....the outer v made from a steel that had good edge retention properties, and the hollow in the v filled with a steel that was tougher for flexibility. The japanese had there metalurgy down. This would be how I would think it would be constructed, but I could be wrong. :)

Ah, yes, I think I understand now. So if I were to grind away the sides of the blade, I would eventually hit ZDP there too, right?araneae wrote:Not quite sure about your diagrams, but I don't think you have it right yet. The Zdp is in fact sandwiched between 420, however the way the knife is ground means that below the lamination line you only see ZDP. The cutting edge is pure ZDP. Higher up to the spine you have a sandwich of 420.

So I think the answer to both of the above questions is yes. Does that make sense?

Interesting concept.

To the fellow above:

Here is what someone wrote about ZDP-189 in a post about steels:

http://www.britishblades.com/forums/sho ... php?t=1190ZDP-189 (various) This steel has astonishing wear resistance and is able to maintain a reasonable level of toughness at Rc-67! That is astounding. It takes a very polished finish and seems to be a fine grained steel. I have never used a blade that held its edge so long and cut so cleanly. However... there are a few things to consider. Not an easy knife to sharpen and the knife will assuredly chip if used hard or used in a serrated edge. Stain resistance is also well below par for a stainless steel. It has a huge amount of Carbon though so thats to be expected. Works better in my opinion when laminated with a softer steel. NOT a knife steel for hard working larger knives or choppers. Ideal for smaller folding and fixed blades where cutting and not chopping is the intended use. Would be excellent in a skinner.

- The Deacon

- Member

- Posts: 25717

- Joined: Fri Sep 24, 2004 10:33 am

- Location: Upstate SC, USA

- Contact:

Closest of your diagrams are "Case A" and the lower of the two side views. In reality, the three layers are of approximately equal thickness rather than the ZDP being significantly thinner. You can see that when looking down at the spine of the blade. From the side, everything below the lamination line is ZDP.

Paul

My Personal Website ---- Beginners Guide to Spyderco Collecting ---- Spydiewiki

Deplorable :p

WTC # 1458 - 1504 - 1508 - Never Forget, Never Forgive!

My Personal Website ---- Beginners Guide to Spyderco Collecting ---- Spydiewiki

Deplorable :p

WTC # 1458 - 1504 - 1508 - Never Forget, Never Forgive!

From my understanding, the construction is different.

The Japanese blades were like that on the left. This is because they used one steel, but differentially tempered it (by coating the upper part with clay to cause different cooling rates, and thus different crystalline structures in the steel) so that the uncoated section would fully harden, resulting in an edge with better edge-holding properties, while the spine would be softer and tougher. The hamon that can be seen is the line where the two different structures meet.

A laminated blade is like that on the right, where a steel with high edge retention is used as the core, while a tougher steel is laminated on each side of it. This allows the blade to be treated to a higher RC without becoming too brittle, as the cladding supports it.

Of course, proportions in the image are not accurate.

The Japanese blades were like that on the left. This is because they used one steel, but differentially tempered it (by coating the upper part with clay to cause different cooling rates, and thus different crystalline structures in the steel) so that the uncoated section would fully harden, resulting in an edge with better edge-holding properties, while the spine would be softer and tougher. The hamon that can be seen is the line where the two different structures meet.

A laminated blade is like that on the right, where a steel with high edge retention is used as the core, while a tougher steel is laminated on each side of it. This allows the blade to be treated to a higher RC without becoming too brittle, as the cladding supports it.

Of course, proportions in the image are not accurate.

- Attachments

-

- Blade Construction.GIF (2.41 KiB) Viewed 2342 times

Will

"No one wants to look the fool. Everyone does the best they can. If they knew better, they'd do better" - old woman on the railway tracks to Sal.

Avatar by Datan!

"No one wants to look the fool. Everyone does the best they can. If they knew better, they'd do better" - old woman on the railway tracks to Sal.

Avatar by Datan!

-

Ed Schempp

- Member

- Posts: 797

- Joined: Fri Sep 24, 2004 10:33 am

- Location: Ephrata, Washington USA

San Mai

There are many ways to construct San Mai but regardless of the method the highest Carbon material is on the edge. Depends on the school of blade smithing whether the high Carbon material was bent in a "U" and a low Carbon piece was inserted for the spine of the Blade or if the low Carbon material was bent into a "U" shape and the high Carbon core was inserted for the edge of the Blade. Modern Sa Mai is a three layer laminate with the Core of the material being the high Carbon material and the outside or Clad being a low Carbon material. Any of these methods build a synergy between the materials. The properties of the San Mai are a blend of the properties of the parent materials and are usually much greater in scope of performance than either steel by itself.

Heat treatment of the materials used in the San Mai mix must be compatible. San Mai was arrived at in many cultures though out man's history mainly because or the lack of good High Carbon steel.

At Finch forge in the Dartmouth Moor high Carbon blister steel was forged in the core of wrought iron billets to make San Mai material for agricultural tools. This technology has been used for over 1000 years. Generally the best edged weapons of most every culture ended up with this technology...Take Care...Ed

Heat treatment of the materials used in the San Mai mix must be compatible. San Mai was arrived at in many cultures though out man's history mainly because or the lack of good High Carbon steel.

At Finch forge in the Dartmouth Moor high Carbon blister steel was forged in the core of wrought iron billets to make San Mai material for agricultural tools. This technology has been used for over 1000 years. Generally the best edged weapons of most every culture ended up with this technology...Take Care...Ed