Page 1 of 5

Who's getting the new mule?

Posted: Mon Mar 16, 2015 2:00 pm

by Surfingringo

Just curious. Does anyone have any solid information on this steel? Has it been used in any production knives? I am not a huge "tester" so I don't purchase every mule. Actually there have only been a few announced here since I joined the forum and I have not purchased any of them. I am waiting for something that I will have more relevant input on like something that is designed for high corrosion resistance. I was thinking to wait and get one of the (possible) upcoming nitrogen steels but this one might be worth testing for extreme corrosion reaistance on the ocean. Not sure; info or thoughts?

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 2:16 pm

by Johnnie1801

I have been searching on google for more info on this steel but I haven't found much. I hope others here can give us more info. Personally, I was more intrigued by CPM 20cv and Maxamet but I would still like to know more about cts b70p

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 3:51 pm

by derrelw

I'm very interested but awaiting input from others more educated in cts b70p...........

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 5:37 pm

by Cliff Stamp

I think it is a very interesting steel as what you have is something very similar to 19C27/MBS-26 with a small amount of MC carbides (~1%). There are lots of very high MC carbide steels with 4-10% MC carbide volume but not a lot of quality knives in the middle ground. Now I like AEB-L and similar steels, but there are times when you don't want fine / high sharpness edge retention but jumping from AEB-L to S35VN is a huge step, and moves steels away from being sharpened on traditional/natural abrasives for example. It would be nice to see this with a 1100 C soak, oil quench, extend to low temperature, multiple low tempers 350-400 F.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 5:43 pm

by Skidoosh

I'm always in for a mule but it seems like several of the steel are described as "a more corrosion resistant form of D-2." We already have CTS-XHP (that I really like). I'm wondering what the difference is between PSF27 and this new steel, they are both spray formed.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 6:16 pm

by PayneTrain

I'm thinking about it, but it will probably be an impulse buy if I do get one.

Cliff, what do you mean by MC carbide? Molybdenum?

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 6:26 pm

by JNewell

I will. I've got at least one going all the way back to MT01. It's sorta like Charlie on the MTA, I can't get offa this train. :spyder: :D

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 6:58 pm

by jtoler_9

I am usually the first in line at the Mule party. But I think I may have to pass. I know nothing about this steel and the price seems a bit higher than I would like for an unknown. Plus at that price, I have had my eye on a Perrin Bowie. Think I'll go that route instead.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 7:01 pm

by Cliff Stamp

Skidoosh wrote:I'm wondering what the difference is between PSF27 and this new steel, they are both spray formed.

CTS B70P isn't spray formed, it is a HIP PM steel .

CTS-B70P compared to PSF27, would be similar to say MBS-26 vs ATS-34. I think it would make an interesting choice, though expensive maybe for Spyderco's kitchen line. I have loaned kitchen knives to friends and while I tend to prefer steels similar to 14C28N, a lot of the knives I get back are way more heavily damaged on the edge than the knives I personally use and are way duller. For that kind of use a higher carbide steel would be of benefit but it might not be wise to jump way up to the 4-10% MC carbide steels.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 7:14 pm

by Cliff Stamp

PayneTrain wrote:Cliff, what do you mean by MC carbide? Molybdenum?

Carbides are normally described in shorthand by generic chemical forumlas. A MC type carbide just means something+carbon which forms in a close to 1:1 ratio. For example one atom of say vanadium and one atom of carbon combine to form vanadium carbide.

In contrast chromium carbide forms much more complex structures such as M7C3 and M23C6. These structures are generally far larger and they are much softer than MC carbides, though still far harder than steels. This is critical in steel design and Crucible was one of, if not the first to really see the potential there for generating high toughness at a given wear resistance by altering steels to form mainly MC type carbides. Now before you get too excited and want to maximize MC carbide there is a pretty serious drawback both apex stability and grindability fall off fast as carbide volume increases.

Steels become very hard to grind and become impossible to grind on traditional abrasives as vanadium, niobium and tungsten carbides volume increases as these are all way harder than silica (quartz is a common natural abrasive, arkansas stones for example). They are in fact even harder than alumina so they really wear stones/abrasives. This is why wood workers tend to not be found of extreme MC carbide steels and why 10V has constantly failed to impress them even though many people have tried chisels, planes, etc. .

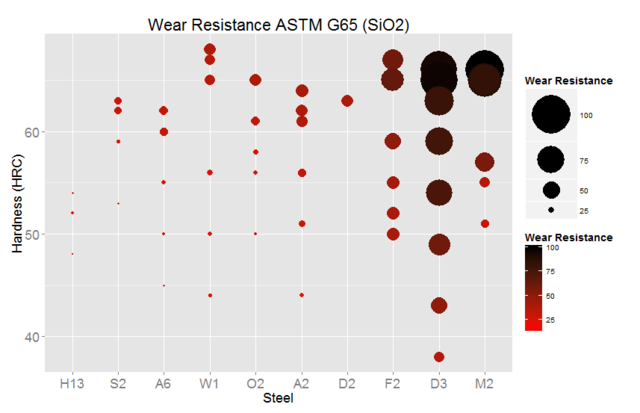

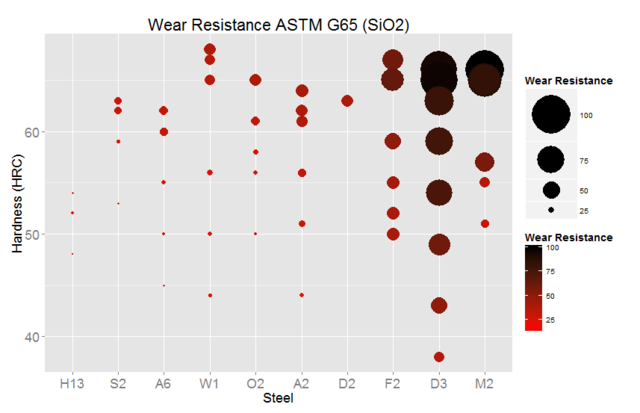

Here is the wear resistance of some common steels over a range of hardness. The wear resistance is measured by a standard ASTM test which consists of grinding the steel against silica abrasive. Note the huge change / increase in wear resistance when you hit F2 which increases again at D3/M2 which are all very high in MC carbides. Even though steels such as W1 can get very hard, 66/67 HRC, they can still be ground on traditional stones, but HSS and high MC carbide steels in general demand a harder abrasive and more careful attention to the binder.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 7:31 pm

by CBro

Good information, thanks Cliff.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 9:13 pm

by Skidoosh

Cliff Stamp wrote:Skidoosh wrote:I'm wondering what the difference is between PSF27 and this new steel, they are both spray formed.

CTS B70P isn't spray formed, it is a HIP PM steel .

CTS-B70P compared to PSF27, would be similar to say MBS-26 vs ATS-34. I think it would make an interesting choice, though expensive maybe for Spyderco's kitchen line. I have loaned kitchen knives to friends and while I tend to prefer steels similar to 14C28N, a lot of the knives I get back are way more heavily damaged on the edge than the knives I personally use and are way duller. For that kind of use a higher carbide steel would be of benefit but it might not be wise to jump way up to the 4-10% MC carbide steels.

Cliff- I'm confused, the description Spyderco posted is

However, rather than being poured into ingot molds, the molten steel is

forced through a nozzle under high pressure to create a spray of small spherical droplets that quickly solidify into powder particles. The small size of the particles forms micro-ingots, drastically reducing the alloy segregation in the steel and ensuring an extremely fine, uniform carbide structure.

Does the spray create the powder or is it sprayed for the blank?

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 9:31 pm

by Cliff Stamp

Spray forming and PM processing are both similar in that they produce essentially a very fine mist of molten steel. In spray forming this mist is sprayed at a target where it solidifies into an ingot. In PM the power is collected and then HIP (squashed) to form an ingot under high pressure/heat. A spray formed billet can be HIP as well but typically isn't due to cost.

They both thus essentially "spray" steel, but one sprays it into a powder and the other into an ingot directly. Spray forming can be thought of as basically like a step towards PM steels. It is lower in cost and produces a product which does similar to what a PM steel does but not to the same extend. it is thus finer than conventional casting and more homogeneous but not as much as PM steels.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 9:34 pm

by Cliff Stamp

In regards to knives, with rare exceptions, they are not made from direct cast steels, as in some kind of mold is made and that is filled with a steel in the shape of a knife. Even PM steels are subjected to further thermo-mechanical treatment to make them both available in suitable stock thickness as well as effect their sub-structure. The steels will typically be rolled, often cross rolled if there is an extreme demand for axial properties, and usually normalized or annealed depending on the final form and can be further formed into bars, strips, or even intricate direct forms. Given the high cost of modern steels, rolling is starting to be advocated vs grinding for even such things as gear shaping.

Re: Who's getting the new mule?

Posted: Mon Mar 16, 2015 11:56 pm

by The Mastiff

I've wanted to try this since I saw Carpenter announce it. Seems like it was a good choice to me.

Joe

Re: Who's getting the new mule?

Posted: Tue Mar 17, 2015 12:47 am

by Ankerson

The Mastiff wrote:I've wanted to try this since I saw Carpenter announce it. Seems like it was a good choice to me.

Joe

Yeah looks like it might do well. :)

Looks like it may be an improvement over XHP, but time will tell I suppose.

Re: Who's getting the new mule?

Posted: Tue Mar 17, 2015 2:11 am

by QUICKSILVER

Posted this in the original announcement thread but it may be more appropriate here so this is a slightly modified repeat.

The steel is very similar in composition to CTS75P used in Mule Team 15.

CTS70P 1.10 C, 0.40 Mn, 0.025 Max. Ph, 0.01 Max. S, 0.30 Si, 14.00 Cr, 2.00 Mo, 0.25 Nb, 1.00 V, Bal. Fe

CTS75P 1.15 C, 0.5 Mn, 0.30 Si, 14.4 Cr, 3.95 Mo, 1.25 V, 80.45 Fe

There is less of every alloy element except Silicon with the addition of 0.25% niobium. Most of them are reduced just a little but the Vanadium is about halved.

I wonder how it will compare to MT15? I wonder what the rational was for using this steel? Are edge retention, toughness, corrosion resistance or ease of sharpening improved? Or is it cheaper or easier to process with similar performance? Other reasons?

Am I reading too much into the similarity of the two steels?

I will be buying 2 when they become available on the 27th.

Bill Maier

Re: Who's getting the new mule?

Posted: Tue Mar 17, 2015 4:27 am

by Bodog

Carpenter says the steel is very suited for cutlery so I'm wondering if Spyderco is simply getting a new steel out there in people's hands based on the manufacturer's recommendation without necessarily any regard to the steel outperforming whatever else is out there from a user's perspective. I have no problem with that and appreciate that it's now out there to try out. With the obvious lack of info available about the steel, the mule project seems like a perfect fit.

Re: Who's getting the new mule?

Posted: Tue Mar 17, 2015 4:31 am

by Bodog

"Carpenter CTS B70P alloy is a high-chromium, air-hardening steel containing additions of molybdenum, vanadium and niobium. The fine, uniform carbide structure provided by the P/M processing improves edge retention and grinding/polishing characteristics which make the alloy an excellent candidate for cutlery applications."

http://www.cartech.com/ssalloysprod.aspx?id=4397" onclick="window.open(this.href);return false;

Re: Who's getting the new mule?

Posted: Tue Mar 17, 2015 4:52 am

by The Mastiff

Quicksilver, CTS B75 has much more Moly. It's actually a high speed steel, bearing steel with corrosion resistance. Powder BG42 which is the stainless version of M50 HS bearing steel It should heat different and have some differences that aren't easy to see by just looking at compositions. I have been looking forward to trying this one though. BG42, the ingot version of B75 is no stranger to me. This one is.I've never tried CRB 7 either. Until I try it, feel it on the stones and try different angles and grits I can't say anything about this one. It is interesting though and I look forward to it.

I haven't missed a Mule yet, but I could be mistaken on that.

joe