Who's getting the new mule?

- jackknifeh

- Member

- Posts: 8412

- Joined: Fri Jul 09, 2010 6:01 am

- Location: Florida panhandle

Re: Who's getting the new mule?

I've never gotten a Mule. May need to try one. I do like to make handles.

I would need a sheath though. I doubt if I would be satisfied with the custom sheaths I make out of pizza boxes. :)

I would need a sheath though. I doubt if I would be satisfied with the custom sheaths I make out of pizza boxes. :)

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

Here is B75P :

Austenized, 2050F, final HRC 62, very fine grain, ~ASTM 10.

I don't have a corresponding micro-graph of B70P, but as Joe noted, it has a much lower Molybdenum content which not only means it was designed for hot temping, the molybdenum significantly changes the chromium/carbon interaction and changes the free element / carbide volumes in solution. Molybdenum will dissolve in chromium carbide, it also will form direct molybdenum carbide and thus it reduces the free carbon. It however strongly increases corrosion resistance, though that is typically off set due to the way they are hardened.

The final forms of them would be different as one steel would have mainly martensite with primary carbide, but the other, as it is hot tempered would have a strong secondary carbide precipitation layer and an extremely low retained austenite fraction due to secondary hardning. B75P would thus have increased :

-hardness

-wear

but lower :

-grindability

-toughness

and corrosion resistance would be extremely sensitive to how they were hardened, but generally favor B70P.

It would be very interesting to see if someone with two Mules could actually see in use these material properties having an influence as we have to take care that they are in practice very small. Keep in mind in industry even small changes like 5-10% can be critical as margins can be that size. But use in hand, trying to see such small changes is very difficult.

Austenized, 2050F, final HRC 62, very fine grain, ~ASTM 10.

I don't have a corresponding micro-graph of B70P, but as Joe noted, it has a much lower Molybdenum content which not only means it was designed for hot temping, the molybdenum significantly changes the chromium/carbon interaction and changes the free element / carbide volumes in solution. Molybdenum will dissolve in chromium carbide, it also will form direct molybdenum carbide and thus it reduces the free carbon. It however strongly increases corrosion resistance, though that is typically off set due to the way they are hardened.

The final forms of them would be different as one steel would have mainly martensite with primary carbide, but the other, as it is hot tempered would have a strong secondary carbide precipitation layer and an extremely low retained austenite fraction due to secondary hardning. B75P would thus have increased :

-hardness

-wear

but lower :

-grindability

-toughness

and corrosion resistance would be extremely sensitive to how they were hardened, but generally favor B70P.

It would be very interesting to see if someone with two Mules could actually see in use these material properties having an influence as we have to take care that they are in practice very small. Keep in mind in industry even small changes like 5-10% can be critical as margins can be that size. But use in hand, trying to see such small changes is very difficult.

-

Commendatore

- Member

- Posts: 275

- Joined: Mon Mar 05, 2012 1:39 pm

- Location: Austria

Re: Who's getting the new mule?

I will skip this one.

Having a handful of steels to choose from that are being compared to D2 this one, just like PSF27 doesn't lure me. Especially as € seems to fall constantly.

I was a little disappointed hoping for cast 440C, Maxamet or 10V Mules and my D2 encounters have not been good so far.

I like the Mules presenting a large variety of steels but this one seems to be redundant for me-might be different for others seeking a new flavor of the D2-class.

Having a handful of steels to choose from that are being compared to D2 this one, just like PSF27 doesn't lure me. Especially as € seems to fall constantly.

I was a little disappointed hoping for cast 440C, Maxamet or 10V Mules and my D2 encounters have not been good so far.

I like the Mules presenting a large variety of steels but this one seems to be redundant for me-might be different for others seeking a new flavor of the D2-class.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

This isn't a steel similar to D2, much lower carbide volume.Commendatore wrote: Having a handful of steels to choose from that are being compared to D2 ...

D2 is one of the most heavily used tool steels, almost everyone makes a high carbon 12% Cr cold work steel and everything tends to get "it is like a X version of D2" by default as people recognize D2.

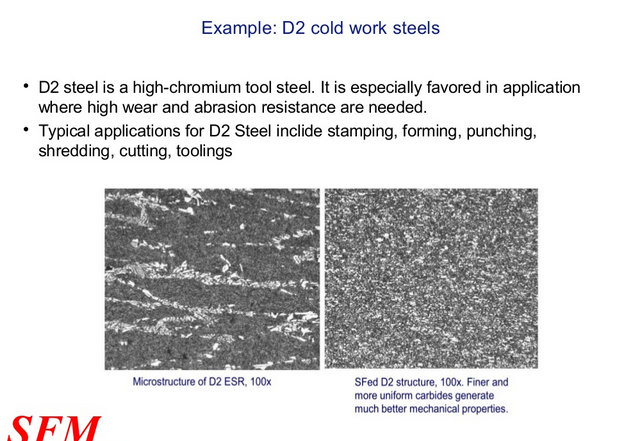

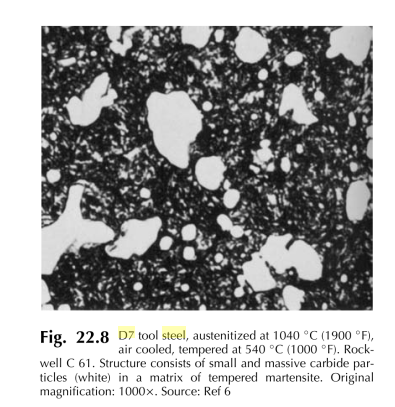

Here is D2 :

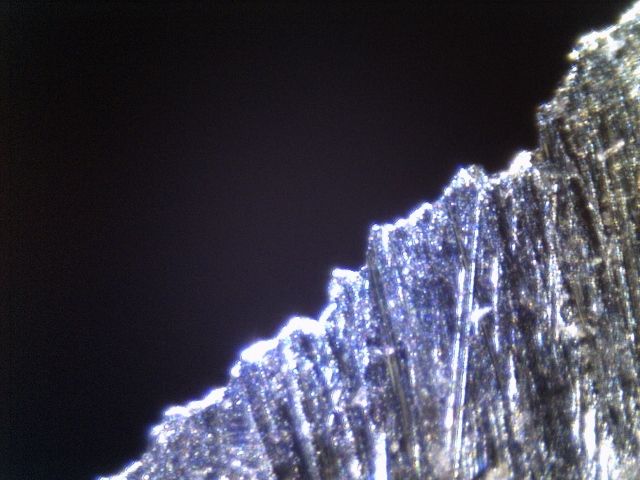

Here is a steel very similar to the new Mule :

And this is A2 :

Carbide size and volume wise, it is closer to A2 than D2.

Re: Who's getting the new mule?

I'd like to buy every mule, but when money is tight I hold off for the standout steels. It sounds like the differences between this and other steels might be too subtle for me to notice, so I'll hold off given the price.

That said, this looks like a very clean steel, and it'd be cool to see it used in production models.

That said, this looks like a very clean steel, and it'd be cool to see it used in production models.

- The Mastiff

- Member

- Posts: 5951

- Joined: Sun Jun 04, 2006 2:53 am

- Location: raleigh nc

Re: Who's getting the new mule?

Cliff,

looking at the picture you posted of the B75 really illustrates the difference PM processing makes. It looks completely different from pictures I've seen of the Ingot BG42.

I have the mule but haven't really put much time into it. Seeing that image makes me want to get it back out of the box. That really is an amazing difference!

Thanks Cliff, and thanks for explaining more what the different composition and extra moly can do. I was hoping you would chime in on that one.

Joe

looking at the picture you posted of the B75 really illustrates the difference PM processing makes. It looks completely different from pictures I've seen of the Ingot BG42.

I have the mule but haven't really put much time into it. Seeing that image makes me want to get it back out of the box. That really is an amazing difference!

Thanks Cliff, and thanks for explaining more what the different composition and extra moly can do. I was hoping you would chime in on that one.

Joe

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

Yes, ingot BG-42 is similar to ATS-34, but the carbide structure is typically finer because it is usually hot tempered and at very high tempers the chromium carbides will dissolve. The interesting thing about carbide type is that you can find arguments for large carbides increasing performance in knives, Boye is the classic reference for that speaking of coarse edges and slicing. It would be kind of interesting to look at two steels, identical in composition with traditional cast, cross rolling, friction stir processed, spray formed, and HIP/PM, and look at the difference in edge retention as a function of grit in slicing and then push cutting.

Re: Who's getting the new mule?

Cliff Stamp wrote:This isn't a steel similar to D2, much lower carbide volume.Commendatore wrote: Having a handful of steels to choose from that are being compared to D2 ...

D2 is one of the most heavily used tool steels, almost everyone makes a high carbon 12% Cr cold work steel and everything tends to get "it is like a X version of D2" by default as people recognize D2.

Here is D2 :

Here is a steel very similar to the new Mule :

And this is A2 :

Carbide size and volume wise, it is closer to A2 than D2.

Um, looking at those pictures the D2 has a scale of 10 um while the B75 has a scale of 30 um. The carbides are all about the same size. The A2 steel doesn't have a scale to reference so I believe those pictures don't prove anything more than the carbides between D2 and B75 are about the same.

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

The carbide volume in D2 is significantly higher so the primary aggregate carbides often intersect and form macro-chains much larger than the average carbide size. In the picture there is an example of this where the clustering produces a chunk about 30 x 50 microns in size.Bodog wrote: Um, looking at those pictures the D2 has a scale of 10 um while the B75 has a scale of 30 um. The carbides are all about the same size.

It is the same as the stainless steel one. Again, it isn't simply about the primary aggregate size but the volume. The volume strongly influences the clumping of the carbides, the grindability, impact toughness, wear resistance, etc. .The A2 steel doesn't have a scale ...

Re: Who's getting the new mule?

Yeah but the A2 has a much lower volume than the B75. Of course D2 has a high carbide volume with B75 being slightly less and A2 being much less while all of the carbide sizes remain fairly equal and D2 clustering somewhat more. I'd like to see photos of PSF27 or CPMD2 compared to the B75 photo to see if there's a real differenceCliff Stamp wrote:The carbide volume in D2 is significantly higher so the primary aggregate carbides often intersect and form macro-chains much larger than the average carbide size. In the picture there is an example of this where the clustering produces a chunk about 30 x 50 microns in size.Bodog wrote: Um, looking at those pictures the D2 has a scale of 10 um while the B75 has a scale of 30 um. The carbides are all about the same size.

It is the same as the stainless steel one. Again, it isn't simply about the primary aggregate size but the volume. The volume strongly influences the clumping of the carbides, the grindability, impact toughness, wear resistance, etc. .The A2 steel doesn't have a scale ...

They who dance are thought mad by those who do not hear the music.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

- The Mastiff

- Member

- Posts: 5951

- Joined: Sun Jun 04, 2006 2:53 am

- Location: raleigh nc

Re: Who's getting the new mule?

Cliff, When CPM D2 first began making rounds with smaller one guy type knife shops a couple of them I know were not satisfied because they felt for the higher price, the smaller, less blocky structure lowered performance over ingot D2 in certain media that D2 is used for. Things that do well with more bite like skinning or caping blades. I can't say how they were heat treating it and have often wondered if it was more the price increase than actual lowered performance. I just remember the talk. I personally like CPM D2 but never found it to act much like the D2 I was used to.Yes, ingot BG-42 is similar to ATS-34, but the carbide structure is typically finer because it is usually hot tempered and at very high tempers the chromium carbides will dissolve. The interesting thing about carbide type is that you can find arguments for large carbides increasing performance in knives, Boye is the classic reference for that speaking of coarse edges and slicing. It would be kind of interesting to look at two steels, identical in composition with traditional cast, cross rolling, friction stir processed, spray formed, and HIP/PM, and look at the difference in edge retention as a function of grit in slicing and then push cutting.

When I first used the CPM Cruwear after years of ingot Vasco and Cruwear I felt I noticed a difference and began running the edge grit a little lower to compensate. I always wondered if it was my imagination, or just the heat treatment making a difference. I have had no real way of telling discounting my experience with just a few knives with no real knowledge about their processing or actual Scientific method to test it.. The B75 Mule likewise I guess I judged less objectively than I should have because I by this time presumed this effect would hold true in comparison to all my BG42 knives.

Cutting rope to dullness wouldn't test the particular Idea I was forming. I know full well I'm able to trick myself into an opinion but to this day when preparing beef or venison jerky and slicing those large roasts I do grab the Ingot mule.

We do have an unusually strong ability to see what we want to see and not what's really there and it pertains to are choices of significant others, politicians, all sorts of things. We have no problem fooling ourselves.

joe

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

This is a common argument, and it is one of those statements that falls under the Pauli criticism, that isn't even wrong. The problem is when you make a statement, if it isn't sufficiently precise then it can't be evaluated, it isn't true or false, it isn't a proposition.The Mastiff wrote: Cliff, When CPM D2 first began making rounds with smaller one guy type knife shops a couple of them I know were not satisfied because they felt for the higher price, the smaller, less blocky structure lowered performance over ingot D2 in certain media that D2 is used for.

Now we can consider that idea and make propositions, such as :

-when sharpened to 600 DMT / 25 micron, CPM D2 shows less sharpness (and/or edge retention) on a draw than traditional ingot/wrought D2 in slicing both leathers and natural animal skins

This is very easy to either confirm or falsify as sharpness on a draw can be measured both quantitatively and qualitatively by looking at how much draw is required to make a cut, or how much force on a given draw length is required to make a cut. While I have heard this claim a lot, I have not heard the justification being provided to the same extent.

But, lack of evidence doesn't mean a claim is wrong, and ignoring all claims due to lack of evidence isn't always the best approach as there are lots of people who produce interesting ideas but have no real care/concern or maybe even ability to provide justification. The first thing I would say is that when forming an edge, the grit used determines the finish far more so than the carbide volume.

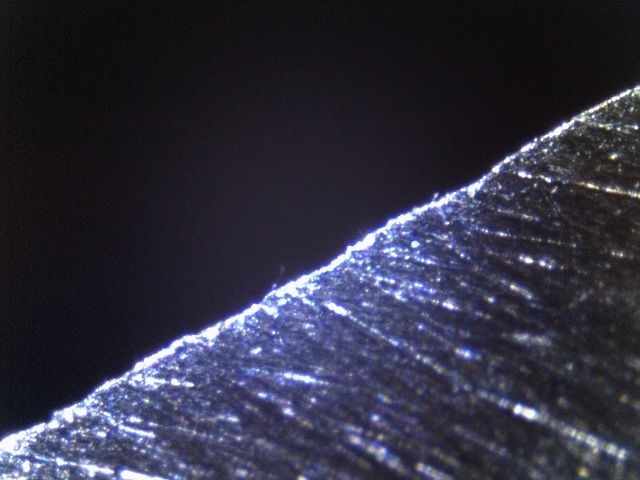

Consider :

+

These are the same steel, two radically different grit sizes. It is a very low carbide steel, 3Cr13, and can still achieve a very high slicing aggression due to forming a very coarse edge as long as a low grit abrasive is used. It is also possible to achieve very high push cutting sharpness on an extremely high carbide steel. Thus looking at initial sharpness, I don't think there is justification for some kind of performance claim.

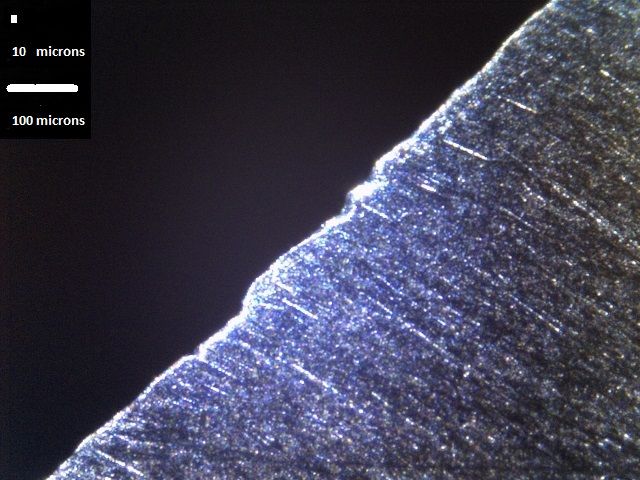

However, when you look at how the knife blunts/wears in use, then something very different happens. Take a look at these :

+

These are worn edges, same angle, same initial grit finish. Can you guess which one is the very high carbide steel? The difference is very obvious in use, one edge wears smooth, the other one wears more irregular. I can see then someone who prefers coarse edges and does mainly slicing would prefer the second type of wear over the first.

This is why I would be curious to see how those people would react to steels such as D3 and D7 vs the PM steels (M4, 10V, etc.). The D series steels also have very high wear resistance, especially D7, but when traditionally made is really coarse/blocky. From "Elements of Metallurgy and Engineering Alloys" :

I would be curious to see the people who make that argument for D2, how would they like D7.

- The Mastiff

- Member

- Posts: 5951

- Joined: Sun Jun 04, 2006 2:53 am

- Location: raleigh nc

Re: Who's getting the new mule?

I always like these images. Actually seeing and feeling things helps my process substantially but there again I'm a bit punchy in my old age. Don't quite have the concentration I used to maybe.

I agree with everything you said. D3 should be pretty easy to source but other than Farid I can't say I know anybody that uses it much. D7 I've never seen outside charts on websites listing available options for XYZ parts. I've read that it isn't very tough but has great wear resistance yet has been replaced by newer PM steels made just as wear resistant with better balances of other attributes.

Looking at the images of it though makes me think it could cut pretty savagely until the carbides fell out then repeat if not sufficiently supported. I'd guess thin edges would be out.

Though not as carbide stuffed D3 , or D6 would make actual blades that lasted. To be honest though none of the entire D series would be first choice steels for me.

the 3C13 is what we call 420J ? Lots of those already on the market. You can beat on that stuff shamelessly without bothering it from what I've seen of some very inexpensive Chinese models. That's also in the Original Grasshopper knives too I believe.

Joe

I agree with everything you said. D3 should be pretty easy to source but other than Farid I can't say I know anybody that uses it much. D7 I've never seen outside charts on websites listing available options for XYZ parts. I've read that it isn't very tough but has great wear resistance yet has been replaced by newer PM steels made just as wear resistant with better balances of other attributes.

Looking at the images of it though makes me think it could cut pretty savagely until the carbides fell out then repeat if not sufficiently supported. I'd guess thin edges would be out.

Though not as carbide stuffed D3 , or D6 would make actual blades that lasted. To be honest though none of the entire D series would be first choice steels for me.

the 3C13 is what we call 420J ? Lots of those already on the market. You can beat on that stuff shamelessly without bothering it from what I've seen of some very inexpensive Chinese models. That's also in the Original Grasshopper knives too I believe.

Joe

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

To be frank, it is hard to argue for something like D3//D7 in modern industry compared to spray/PM steels which can have the same wear resistance (or greater) and much higher toughness with a far less axial dependence. I am just curious as to the experience of those who really like the chunky steels. I would also be curious of the following :

-as cast steel, the dendretic networks will be an order of magnitude larger than the aggregates even in D7

-coarse grain intentionally, this is just a very loose guess but it would seem to me it would be likely to create a similar jagged/chippy edge

-knives cut cross grain

The last one I keep thinking about for a couple of reasons. One of which is that the compressive strength is actually maximized that way. Now the impact toughness is really reduced, it would be really poor to do it for any kind of prying/impact knife - but for a skinner or similar, I would be really curious if a D2 blade was cut perpendicular to the rolling direction so the carbides would run spine to edge.

-as cast steel, the dendretic networks will be an order of magnitude larger than the aggregates even in D7

-coarse grain intentionally, this is just a very loose guess but it would seem to me it would be likely to create a similar jagged/chippy edge

-knives cut cross grain

The last one I keep thinking about for a couple of reasons. One of which is that the compressive strength is actually maximized that way. Now the impact toughness is really reduced, it would be really poor to do it for any kind of prying/impact knife - but for a skinner or similar, I would be really curious if a D2 blade was cut perpendicular to the rolling direction so the carbides would run spine to edge.

-

Cliff Stamp

- Member

- Posts: 3852

- Joined: Sat Dec 31, 2005 2:23 pm

- Location: Earth

- Contact:

Re: Who's getting the new mule?

Same steel, 420 is a really loose range of steels, AISI 420 covers a lot of ground, 420J1/J2 are more specific Japanese steels. I am starting to favor steel labels like 3Cr13 as they are so trivial to interpret.The Mastiff wrote:

the 3C13 is what we call 420J ?

420 is one of those steels, similar to 1095 which is usually poorly judged because of the knives that it is used to make. It is very inexpensive so it gets used in $1 knives for which it is unlikely that there is a lot of effort in processing.

Now for knife which don't see impact/prying, well I would prefer 5Cr13 as there is no reason why not to look at 62/64 HRC with a small < 5% volume of chromium carbides.

Re: Who's getting the new mule?

Hmmm... now I understand why you stressed the importance of not just jabbing your knife into a pocket sheath with one hand the other day. :rolleyes:jackknifeh wrote:I've never gotten a Mule. May need to try one. I do like to make handles.

I would need a sheath though. I doubt if I would be satisfied with the custom sheaths I make out of pizza boxes. :)

K-390 on hand: Mule Team 17, Police 4 G-10, Endela (burlap micarta), Endela backup, Endura (canvas micarta), Straight Stretch (now blade-swapped with G-10 Stretch), Delica Wharncliffe, Dragonfly Wharncliffe, & Dragonfly Wharncliffe shorty mod

Note to self: Less is more.

Note to self: Less is more.

- PayneTrain

- Member

- Posts: 1556

- Joined: Sun Mar 02, 2014 12:30 pm

- Location: CT

Re: Who's getting the new mule?

Reading that makes my edges hurt.jackknifeh wrote:I've never gotten a Mule. May need to try one. I do like to make handles.

I would need a sheath though. I doubt if I would be satisfied with the custom sheaths I make out of pizza boxes. :)

Do what I did. Order some kydex. It's cheap. Then find a foam mat or something and cut that up to use as a press, and you're all set. I think the most expensive part was the tool for setting the rivets, and it was only $12. I love DIY! Just wish I had more time to DI...

- The Mastiff

- Member

- Posts: 5951

- Joined: Sun Jun 04, 2006 2:53 am

- Location: raleigh nc

Re: Who's getting the new mule?

Sorry to side track but I was reading some other material about steel used in WW2 Naval Armor, big guns and in this case the shells and hard caps they use for AP big gun rounds up to the mighty 16 inch. http://www.navweaps.com/index_nathan/index_nathan.htm

It's amazing how soft some of those things are. It puts in perspective just how hard we have our steels in knives now. Even running at rc 56 is way harder than anything they used back then to try to breach Class A armor. The 8 inch AP caps almost look like L6 steel.

The large naval rifle barrels they used on battleships like our museum ship North Carolina not far from here is almost a lost art. Imagine working on one gun barrel over 3 to 4 weeks heating and cooling it while trying to not only machine it but get the grain structure correct. The PSI and velocities were up there with our .308/.303/30-06 which is over 50,000psi. I believe some of the AP components were heated in huge lead pots like they use in a smaller way making Straight edge razors in Soligen.

Amazing stuff. Sorry for the side track.

Joe

It's amazing how soft some of those things are. It puts in perspective just how hard we have our steels in knives now. Even running at rc 56 is way harder than anything they used back then to try to breach Class A armor. The 8 inch AP caps almost look like L6 steel.

The large naval rifle barrels they used on battleships like our museum ship North Carolina not far from here is almost a lost art. Imagine working on one gun barrel over 3 to 4 weeks heating and cooling it while trying to not only machine it but get the grain structure correct. The PSI and velocities were up there with our .308/.303/30-06 which is over 50,000psi. I believe some of the AP components were heated in huge lead pots like they use in a smaller way making Straight edge razors in Soligen.

Amazing stuff. Sorry for the side track.

Joe

Re: Who's getting the new mule?

Interesting link. A lot of it looks way over my head, but I intend to spend some time poking around there.The Mastiff wrote:Amazing stuff. Sorry for the side track.

Joe

It reminds me of a research paper I did for an AP History class way back in high school on the super-heavy siege guns used by the Germans in the first and second world wars. Like you said, amazing stuff. Also kind of terrifying what people come up with to kill each other though.

:spyder: